September 2022 Vol. 77 No. 9

Features

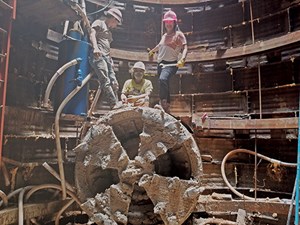

Curved Microtunnel Project Saves Time, Effort

Jeff Griffin | Senior Editor

BRH Garver recently completed two segments of major sanitary sewer system improvements in Houston, employing microtunneling. The bores consisted of 4,600 linear feet and 4,200 linear feet of 60-inch-diameter gravity sewer tunnel at depths to 70 feet. Hazen and Sawyer designed both projects for the owner, the city of Houston.

BRH-Garver served as the primary contractor on the downstream segment, Package 1A, of the Chelford City Diversion program, while installing the upstream segment, Package 1, for prime contractor, Boyer Inc.

In addition to microtunnel installation of 60-inch centrifugally cast, fiberglass-reinforced, polymer mortar pipe (CCFRPMP), the downstream project included trenchless installation of 48-inch CCFPRMP for future connections and polymer manholes. Pipe was supplied by Hobas Pipe USA.

BRH-Garver also constructed a large cast-in-place structure for the downstream connection of the entire Chelford City program on an existing 108-inch sanitary main feeding the Upper Brays Wastewater Treatment Plant.

Microtunneling choice

The decision to use slurry microtunneling, a precise method of excavating a tunnel while simultaneously jacking pipe, was the right choice by the city and designer, according to David Ellett, vice president of BRH-Garver. It provided the accuracy needed for tight line and grade work at the 60-foot-plus installation depths, the varying soil conditions well below the water table, and the high volume of surface traffic above the tunnel alignments.

“The project’s initial design of Segment 1A included 60-inch microtunnel from tunnel shafts located at nine planned manhole locations, making tunnel segments all shorter than 700 feet,” said Ellett. “With our recent purchase of a Herrenknecht AVN 1200 microtunnel system, we were in a good position to propose changes to the project alignment.”

BRH-Garver worked from 24-foot-diameter jacking shafts and 15-foot-diameter receiving shafts.

The Herrenknecht AVN 1200 system includes a 600-ton jacking frame, controls for multiple intermediate jacking stations (IJS), and an automatic bentonite lubrication injection system. BRH-Garver added to their purchase a traditional laser-based guidance system, and the gyroscope-based guidance system, GSN-P, develop by VMT.

Before construction began, BRH-Garver proposed an alternate alignment that combined shorter tunnels, eliminated shafts and utilized a curved microtunnel alignment.

“Our proposal eliminated three manholes and corresponding tunnel shafts,” Ellett said. It changed the nine-drive alignment to three long microtunnel drives, leaving the short downstream drive as designed.

Although the alternate alignment only required five shafts to complete, BRH-Garver’s proposal also included installing manholes needed for future connections after microtunneling was complete.

“VMT input the path of the tunnel into the guidance system, which displayed a virtual laser at the control console,” Ellett explained. “The operator guides the path towards that virtual laser exactly the same as if it was with a standard laser targeting system.”

As the tunnel was excavated, CCFPRMP gravity-flow sewer pipe was simultaneously installed.

The first microtunnel drive was a traditional straight tunnel of 1,436 feet. However, the second drive of 1,609 feet included a 5,130-foot radius curve at a length of 738.9 feet. Herrenknecht and VMT worked with the construction crew to accomplish this initial curved microtunnel.

Next up was tunnel drive number three consisting of 1,502 linear feet with a 4,016-foot radius curve and a curve length of 586.4 feet. The curved microtunnel segments were completed three months ahead of the original design schedule. Overall, the project was completed 85 days ahead of deadline.

Ellett credits successful completion of the revised plan, to hard work by the Garver crew members, support from Herrenknecht and VMT, and the partnership between the contractor, city of Houston and design that led to the curved alignment.

FOR MORE INFORMATION:

BRH Garver, (713) 921-2929, brhgarver.com

Herrenknecht, herrenknecht.com/en

Hobas, (800) 856-7473, hobaspipe.com

VMT, vmt-gmbh.de/en

Hazen, (212) 539-7000, hazenandsawyer.com

Comments