August 2020 Vol. 75 No. 8

Rehab Technology

Rehab Technology

Vortex Companies Adds Diversity, Inclusion Position, New Facilities

The Vortex Companies has promoted Candace Strother to the newly created position of director of Diversity and Inclusion. In this role, she oversees Vortex’s efforts to promote diversity in the workplace through training and education, creating an inclusive environment and promoting respect among peers. She leads a diversity committee, comprised of a balanced cross-section of Vortex employees, to begin building the foundation for a more open and inclusive environment.

Prior to joining the Vortex Companies, Strother worked in the banking and financial services field for over a decade. She is also the founder and CEO of QueenLyfe Inc. (Love. Yourself. First. Every day.), a nonprofit organization dedicated to building an empowered community of women and girls by promoting health and wellness, financial responsibility and mentorship.

“We want to be the vanguard for change in an industry that needs to improve in this area,” said Mike Vellano, CEO of the Vortex Companies. “With Candace’s guidance, our goal is to make Vortex a place where people know they will be treated equally and appreciated for their talent, regardless of race, culture, sex or age.”

Vortex also opened two facility locations to support its growing team of trenchless infrastructure professionals and meet the needs of customers in the southeastern region.

A new, 14,000-square-foot building in Tampa supports the Florida Vortex Services group. The space is a major upgrade for the team, featuring training and conference rooms; storage space; large, secured storage yard for vehicles and equipment; and a separate maintenance and repair shop.

In Winder, Ga., an 8,000-square-foot building also accommodates a growing team and primarily supports operations and installation crews. In addition, it houses equipment and other products required for the increasing number of projects in the Atlanta area.

“The growth affords us opportunities to hire more talented individuals and expand to provide more communities the products and services that are vital to the completion of infrastructure repair and maintenance projects,” said Vellano.

FOR MORE INFORMATION

The Vortex Companies, (713) 750-9081, vortexcompanies.com

Madewell Products Initiates Advisory Council

For nearly 40 years, Madewell has dedicated itself to one thing – researching, developing and producing a breed of restoration mortars and corrosion-resistant epoxy topcoats for structurally enhancing and protecting concrete surfaces.

Capitalizing on the unique Mainstay Composite Liner process acquired from US Steel in 1971, much of Madewell’s strength and market appeal is derived from its execution arm – a network of Certified Applicators in North America. These independent organizations are equipped, trained, and supported by Madewell Tech Services team.

Supported by management decisions and capital investments across the full spectrum of the business, Mainstay-branded products are growing in volume, value, and share of market. The latest strategic contribution is the newly established Madewell Advisory Council (MAC).

This proactive and progressive move will enable decisions to be made as a unified force, with high confidence, and at the speed of business.

Distinguished members of MAC are five executives of top-producing contracting partners among its Certified Applicators:

- Chris Culy, Culy Contracting (Indiana, Tennessee)

- Horacio Franco, H&R Underground (California)

- David Ventresca, Advantage Manhole & Concrete (Maryland, Louisiana, Texas)

- David Reaves, Prism Contractors & Engineers (Virginia)

- James Fleming, National Water Main (Massachusetts, Florida)

FOR MORE INFORMATION

Madewell Products Corporation, (800) 741-8199, madewell.net

Primus Line Overland Piping System Offers Safe, Time- and Cost-Saving Alternative

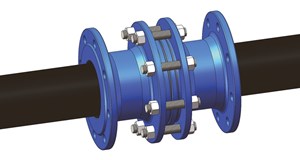

Rädlinger Primus Line GmbH introduced the Overland Piping System as an alternative to using traditional pipe material, such as steel or HDPE, for bypass or transport pipelines during a rehabiitation project.

Traditionally, it can be a time-consuming and costly exercise, as pipe lengths have to be cut and welded to fit to the available route. Similarly, using trucks to transport water can be costly, as well as unreliable, highly labor-intensive, and environmentally damaging.

Instead, the Overland Piping System is supplied as a continuous pipe length of several hundred meters, using the technology Primus Line established in the 1990s for the lining of pressure pipe networks including water, oil and gas mains. This eliminates the need for onsite welding procedures and makes the pipe re-usable for multiple applications.

The system offers improved handling for the operator due to a new liner matrix and it is quick to mobilize and deploy given its lightweight and high material strength.

Not only is the system available for water supply and sewerage removal, but it offers the capacity to transport some hazardous materials, such as water/oil mixes and other wastewater products for relatively short time periods, when necessary.

Materials used in the Primus liner, such as Kevlar, add to the structural integrity of the pipe. The outer layer of the Overland Piping liner is made of thermoplastic polyurethane, making it not only more resistant to chemicals and abrasion, but more flexible. Furthermore, the black outer color eliminates UV degradation, prolonging the pipe’s life expectancy.

FOR MORE INFORMATION

Rädlinger Primus Line GMBH, +49 9971 8088-0, primusline.com

Comments