September 2011, Vol. 66 No. 9

Features

Effects Of Pipe Bursting On Nearby Utilities: Prediction, Prevention And Management

Editor’s Note: The International Pipe Bursting Association (IPBA), a division of NASSCO, is presenting a series of articles in Underground Construction that will provide the reader with a better understanding of the technology. Many myths and misconceptions exist regarding this proven rehabilitation method for replacing existing underground utilities.

This article will discuss the potential impact on adjacent utilities as a pipe is replaced using pipe bursting technology. From concept through design and construction a true understanding of the effects pipe bursting has by your entire team is essential in preventing utility damage and ensuring a successful project.

First and foremost it is important to understand how pipe bursting works and this article will be written with the assumption that the reader has a basic level of understanding for the pipe bursting method and its common applications. (See previous articles beginning with the May edition of Underground Construction.)

As with any construction project, having a management model in regards to risk assessment and reduction is critical. Although many aspects of utility construction, including pipe bursting, cannot predict an exact scope of impact, tools to manage such an occurrence are available through proper design and risk management.

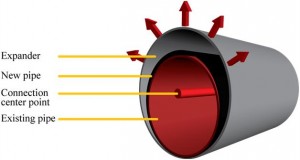

Pipe bursting, whether static or pneumatic, will pull a hardened steel burst head through an existing pipe and expanding the soil which allows a new pipe to follow in its path. The amount of influence a pipe burst will have on the surrounding soils and adjacent utilities is driven by the amount of expansion required and type of soil surrounding the “potential impact area.”

Rule of thumb

To calculate the potential effects, there are a few general rule of thumb calculations. However, these must be modified to account for varying geotechnical conditions. The potential impact zone is calculated by subtracting the inner diameter (ID) of the existing pipe from the outside diameter (OD) of the expander head that is doing the pipe bursting and then multiplying by 10. This will give you in inches an approximate “potential impact zone” where the possibility of damaging another utility exists if previsions are not made.

An example would be an existing 8-inch vitrified clay pipe sewer main being replaced with a new 10-inch high density polyethylene (HDPE) pipe.

A common rule of thumb for determining the size of the expander is that it will be 20-25 percent larger than the OD of the newly installed pipe.

If a 12-inch OD expander head were selected, the potential impact zone would be 12 inches minus 8-inches equals four inches; then multiply by 10-inches which equals 40 inches. Forty inches will be a baseline for determining the amount of separation from the existing pipe center line to adjacent utilities. The example for an eight-inch, size-on-size burst would be 10 inches minus eight inches equals two inches times 10-inches equals 20 inches.

In addition to the simple math that is required to determine amount of oversize for the burst head, a more important but complicated formula is to determine the volumetric displacement of the amount of earth moved in the burst to allow passage of the head through the original pipe ID. For example, the volumetric displacement would be greater for replacing a 10-inch pipe with a 12-inch pipe than it would be for replacing a six-inch pipe with an eight-inch pipe. Either of these scenarios is often referred to as a “one upsize” in pipe bursting lingo. Whereas a six-inch to 6-inch would be a “size-on-size” and a six-inch to a 10-inch would be a “double upsize.”

As stated earlier, geotechnical conditions play a critical role and may impact this potential by as much as double. Sands, loose gravel and small cobble move easily as the burst head travels through the ground and will have smaller potential impact. However, large cobble and some dense soils may have a greater potential impact area. This information should be provided on actual trench conditions and not soil borings provided outside of the original pipeline trench as is common with HDD pre-design.

Direction of force

It is very important to remember that the force exerted during a burst is focused from the center point of the existing pipe upwards and outwards. This helps in designing the utility coordination and mark-out procedures which is where 90 percent of the pre-burst risk management will occur.

Eight-inch ductile iron pipe burst head and an 11.5-inche O.D. expander.

Often times on a project, a utility will be found to be in the potential impact area but will be marked as “actual location of water main to be field determined” which can, in most cases, be done through a small keyhole style hydro-excavation. Once actual invert, pipe size and type is found, it can be noted and either taken off line, removed prior to the burst, or safely passed by the bursting head depending on its proximity to the burst path.

The use of Quality Level A subsurface utility engineering data could potentially predict and prevent all utility strikes caused by pipe bursting. However, that may not always be practical or necessary on all projects. A Quality Level C would be the lowest acceptable level for most pipe bursting projects, but would not be sufficient for crossing “critical” utilities that would cause personal injury or property damage from a rupture. Most utilities being crossed by a traditional pipe burst would be in the order of sanitary sewer laterals, water services, storm drains, intersecting water and or gas mains, sewer force mains or electrical ducts. Most can be accurately estimated based on Level C field data such as opening sewer or storm manholes and shooting invert grades, opening and measuring gate valves or curb stops, or other “simple” field verification methods.

Utility damage prevention is a risk associated with all construction and pipe bursting is no exception. However, through a properly planned, designed and executed project, there have been millions of feet of pipe replaced utilizing pipe bursting technologies throughout the world both safely and without unreasonable risk to those involved or the general public. Experience establishes that more utilities have been damaged installing the insertion pits and receiving pits with excavation equipment than with any amount of pipe bursting.

Do your homework, select a quality project team and let’s go pipe bursting!

Coming in October: Pre-chlorinated pipe bursting for potable water mains.

FOR MORE INFORMATION:

IPBA (NASSCO), (410) 486-3500, www.nassco.org

Comments