August 2024 Vol. 79 No. 8

Features

22 Years of advancing research in underground infrastructure and trenchless technologies: CUIRE's commitment

It is hard to believe that 22 years have passed since the Center for Underground Infrastructure Research and Education (CUIRE) was established. In 2006, the first trenchless technology conference was held at the University of Texas at Arlington (UTA).

CUIRE is dedicated to advancing research, development and training in underground infrastructure technologies, particularly focusing on pipelines. Through collaboration with industry, government agencies and professional associations, CUIRE ensures its programs are both relevant and impactful, addressing the pressing needs of modern infrastructure.

CUIRE has supported trenchless conferences in China, India, Turkey, Malaysia, Hong Kong, Qatar and Abu Dhabi, and helped to establish a trenchless industrial park in China. In March 2022, we teamed up with Buried Asset Management International (BAMI-I) and Utility Engineering & Surveying Institute (UESI) to host a five-day Utility Investigation School (UIS) at UTA.

CUIRE has been assisting the Trenchless Technology & Pipe Conference (TTP) for the Regional South-Central Chapter of NASTT (SC-NASTT), in organizing an annual conference every year. CUIRE also plays a major role in the Underground Infrastructure Conference (UIC) by organizing CUIRE schools every year.

CUIRE leadership has developed graduate and senior-level civil engineering and construction courses in pipelines and trenchless technology, which are offered every summer at UTA. Dr. Mo Najafi, director of CUIRE, had five books published by McGraw-Hill and helped ASCE committees publish several Manuals of Practice (MOPs).

CUIRE is involved in groundbreaking research, with 16 Ph.D. students actively contributing to its projects. Recent endeavors include use of trenchless technologies for comprehensive asset management of culverts and drainage structures, real-time monitoring systems for water assets, and development of innovative pipeline renewal methods.

In addition, research efforts include development of polymeric spray-applied pipe linings (SAPLs) in high-pressure pipe applications, product evaluations for underground stormwater storage, infiltration chambers and modules under highway truck loading. CUIRE is also leading a nationwide study to assess innovative technologies for monitoring water assets. These projects not only push the boundaries of current knowledge, but also offer practical solutions to infrastructure challenges faced by communities nationwide.

SAPL in Pressure Pipes Application

Spray-applied pipe lining (SAPL) can address pipe deterioration and prevent failures when designed based on the host pipe condition. Due to its minimum access requirements, this technology is one of the most cost-effective and versatile trenchless pipeline renewal methods.

Polymeric SAPL is applied inside a pipe for either corrosion prevention or to enhance the load-bearing capacity of the host pipe, by creating a new interactive structure. CUIRE is conducting testing for the application of SAPL in pressure pipelines, process pipelines and industrial applications. The researchers at CUIRE are continuously advancing into developing a testing program to better evaluate the use of SAPL material in pressure pipes based on the different AWWA Structural Classifications.

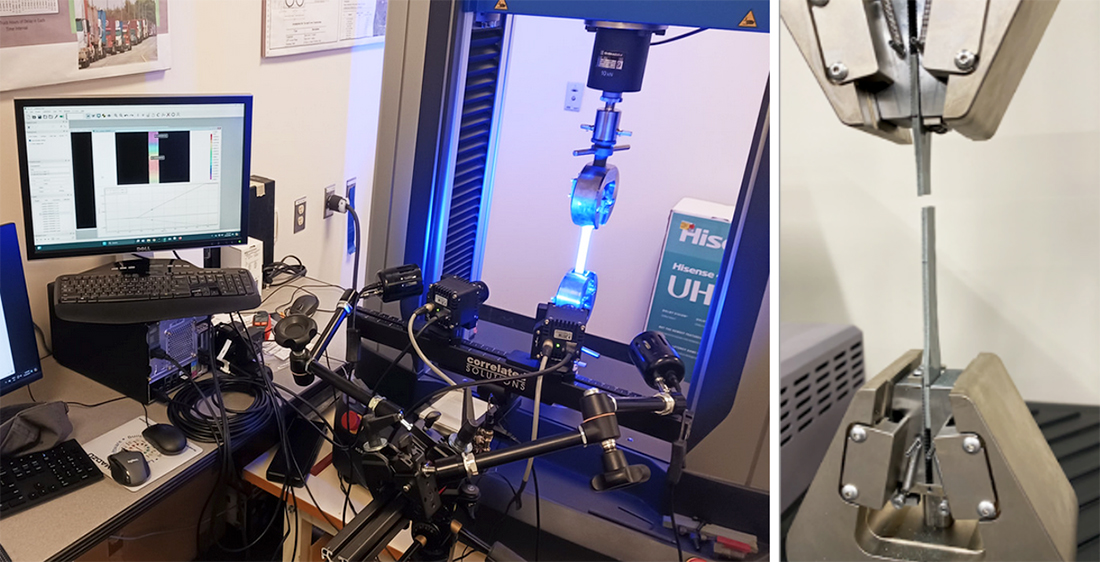

Material Properties Testing

Material properties testing is required to determine the material's mechanical response under various conditions. This can be useful in designing the liner material for different and challenging applications. The properties of polymeric materials are influenced by time, temperature and loading rate. Therefore, we tested these properties at short and long-term time intervals, as well as at different temperatures and loading rates.

These tests show the material’s response against tensile straining due to excessive or continuous loading, resistance to bending, impact resistance, ground movement and temperature changes, and shear impact due to sudden loading for shallow-depth pipes. Figure 2 shows a short-term tensile testing, and Figure 3 presents the short-term flexural testing using a universal testing machine.

To effectively improve the consistency of testing results, a comprehensive approach, considering parameters such as spraying techniques, specimen location, and cutting and spraying conditions, was carefully considered while preparing samples. The material properties obtained from the testing results were used to design the full-scale laboratory testing for Class II, Class III, and Class IV, as per AWWA Structural Lining Classification System.

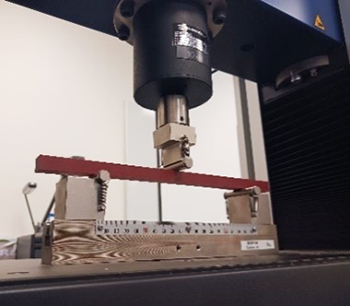

Full Scale Laboratory Testing for the Application of SAPL in Pressure Pipes

A short-term hole-spanning test was performed by researchers at CUIRE for a 30-inch diameter host pipe with hole-spanning sizes of 0.5, 1, 2, 4, and 6 inches. The pipe samples with 0.5-, 1- and 2-inch hole-spanning sizes were lined with pure polyurea elastomeric material, and the lining system passed 500 psi pressure without failure. The 4- and 6-inch hole-spanning testing is still in progress.

The short-term hole spanning test will determine the structural capability of the liner material as per AWWA Class II, which classifies the capacity of the liner material to bridge the corrosion holes in the host pipe under the desired working pressure. Figure 4 shows the pipe sample with a hole and polymeric liner exposed through this hole.

Additionally, evaluating the buckling effect caused by groundwater hydrostatic pressure on polymeric SAPL liners, due to water within the annular space between the liner and the host pipe, is an important criterion for the Class III structural classification system.

Geometric imperfections may exist due to the deteriorated state of the host pipe, inconsistencies in liner installation, or adhesive failure, all of which significantly affect bonding capacity. Non-bonded areas create gaps between the liner and host pipe, through which groundwater may seep, exerting external pressure on the lining system.

Researchers at CUIRE also conducted a short-term external buckling test involving a SAPL liner confined within an 8-inch host pipe. The test evaluated the impact of varying liner thicknesses, while maintaining a consistent annular gap, to determine the liner's short-term resistance to hydraulic pressure and its resistance to buckling effects caused by groundwater.

The short-term hole-spanning and external buckling tests, along with the vacuum pressure test, confirmed the liner's structural properties, as per class II and III. Figure 5 shows the external buckling test assembly and the pipe sample with an annular space between the host pipe and pipe sample, sealed at both ends.

To evaluate the use of polymeric SAPL, per AWWA Class IV, researchers at CUIRE tested the liner material under internal hydrostatic pressure to evaluate its integrity with no support from the host pipe. The testing included 8-inch diameter pipe samples, which were tested at different temperature conditions, from 41 degrees F to 150 degrees F.

Figure 6 shows hydrostatic pressure testing equipment, and Figure 7 illustrates a picture of a broken test sample.

The test results determined the burst pressure, mode of failure, and hoop stress on the SAPL due to internal pressure. The results established a relationship between the pipe thickness and pressure at different temperatures, which is required to determine the material's performance under various environmental and loading conditions.

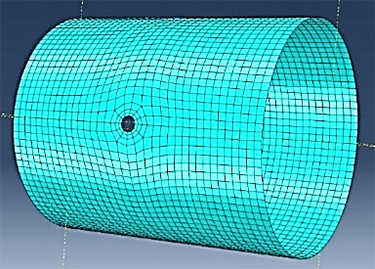

CUIRE is also actively involved in research projects related to the Finite Element Method (FEM). These projects are focused on advancing the understanding and capabilities of structural analysis and numerical modeling for underground infrastructure. Our primary focus is on simulating and developing tests and parametric studies that improve structural methodologies.

One significant project involves conducting 3D FEM analysis on SAPL in pressure pipes applications. This research evaluates the effects of various parameters, such as pipe diameter, pipe thickness, and running these FEMs at different pressure ratings and environmental conditions. By optimizing the thickness of the polymeric material through non-linear FEM analysis, we aim to create a design equation and standard guidelines for SAPL application. Detailed 3D models are developed using ABAQUS software.

The FEM models have been validated through extensive experimental hole-spanning testing, external buckling hydrostatic pressure testing, and pressure integrity testing on full-scale SAPL samples. Figure 8 represents the 3D FEM model with meshing of the hole-spanning sample before applying the pressure to the model. The laboratory model tests replicate real-world conditions, ensuring the reliability of our FEM models.

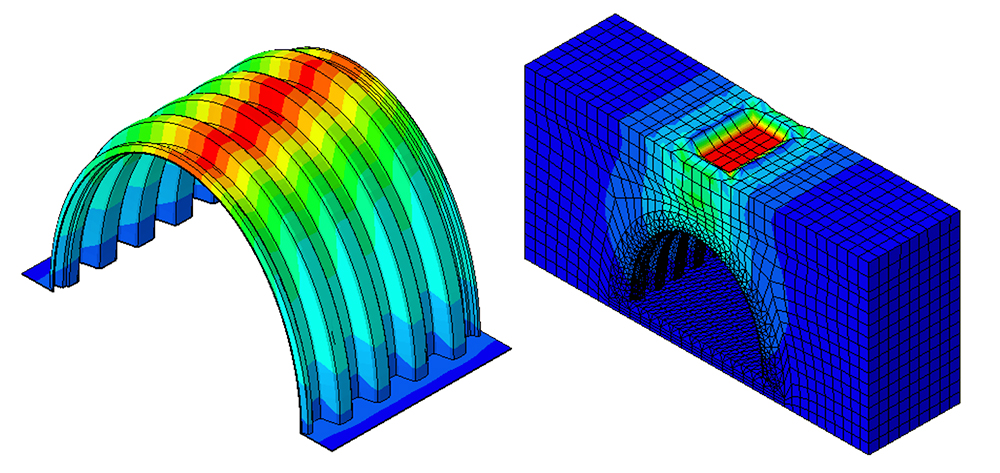

Live Load Testing of Embedded Stormwater Storage, Infiltration Chambers, Modules

CUIRE's extensive research capabilities have led to partnering with Xerxes, a leading innovator in composite underground storage solution products. Together, we are working on creating test procedures and product evaluations for stormwater storage and infiltration chambers and modules. The test procedures determine how well HydroChain stormwater chambers and modules can withstand vehicular and soil loads under various real-world scenarios.

The chambers were embedded in a soil box and then backfilled with aggregates. Highway truck loading was simulated with a 330-kip actuator. During the test, different sets of data, such as load applied with the actuator, deflection at the crown of the chambers, strain and pressure were collected and analyzed to determine the structural integrity of the chambers.

Additionally, CUIRE researchers performed modeling simulations to predict the structural behavior of the embedded HydroChain chambers under various load conditions, as shown in Figure 10. Studying the impact of different design parameters gives CUIRE data that allows for increased structural performance and durability.

Through such research, CUIRE is helping lead the way in improved efficiency and cost-effectiveness of underground infrastructure systems. Sharing our findings through various publications and conferences contributes to industry knowledge and helps utilities make informed decisions about infrastructure technology and maintenance.

Innovative Technologies to Improve Monitoring Water Assets

The Water Research Foundation (WRF) project 5191, entitled "Innovative Technologies to Improve Monitoring of Water Assets," is a comprehensive investigation into the use of condition monitoring technologies by water utilities. The project assesses both existing and cutting-edge technologies to enhance the condition monitoring and management of water infrastructure.

The research examines the published body of knowledge, surveys utility practices and explores case studies from various water utilities. These sources of knowledge then provide the necessary information to identify gaps and conclusions about condition monitoring approaches.

One of the primary objectives is to provide clear, actionable guidelines for water utilities in selecting the most suitable condition monitoring methods for pressure pipelines. This involves a thorough evaluation of technical requirements and effectiveness of different technologies. The project has engaged multiple stakeholders, including notable utilities throughout North America, ensuring a broad spectrum of input and validation.

Figure 11 shows a sample case study for a pump station.

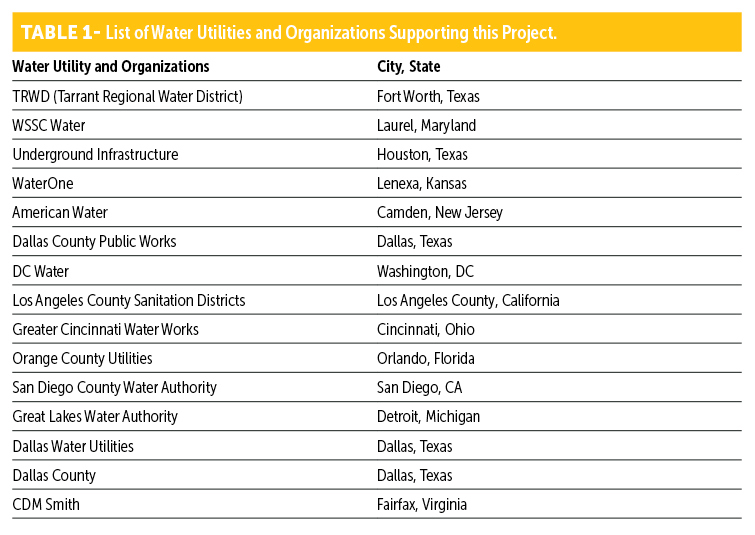

Table 1 presents a list of water utilities and organizations supporting this project. Through workshops, surveys, gap analysis, and collaborative efforts, the project aims to drive significant advancements in the condition monitoring of water assets. Ultimately, this will contribute to more-efficient and -reliable practices across the nation.

Authors: Mo Najafi, P.E., Ph.D.; Kawalpreet Kaur, Ph.D.; Diego Calderon, P.E.; Sanaz Ghalambor, Ph.D.; Ehsan Rajaie

CUIRE Holds Annual Conferences

CUIRE held its 22nd annual trenchless technology inspector training and certification schools on March 18, in Oklahoma City, Okla., in conjunction with the Underground Construction Technology Conference. This year's program included HDD schools for Difficult Soil Conditions and Innovative Technologies for Monitoring of Water Assets. More than 35 professionals attended these courses. The instructors were industry experts and included CUIRE board members and friends.

The following CUIRE Schools will be held in conjunction with the 2025 Underground Infrastructure Conference, on Monday, March 3, 2025, at George R. Brown Convention Center, Houston, Texas. Speakers are included with each school.

Advanced Horizontal Directional Drilling Schools

- Jeff Puckett, P.E., president, J.D. Hair & Associates, Inc.

- Luke Bever, P.E., project manager J.D. Hair & Associates, Inc.

- Nick Strater, PG, Trenchless Practice Leader, Brierley Associates

- Mike Whitehouse, Technical Sales/Fabrication Specialist, ISCO Industries, Inc.

- Weston Peters and Peyton Boyle, Vermeer Corporation

- Dr. Gerhard Lang, project manager, Herrenknecht

- Mark Gallucci, customer insight, Digital Control Incorporated

Innovative Technologies for Monitoring of Water Assets

- Dr. Jian Zhang, Ph.D., PE, research program manager; Dr. Mo Najafi, CUIRE director

- Diego Calderon, Ph.D. candidate, CUIRE Research Associate

- Dr. Vinny Kaushal, CUIRE/UTA

- Ms. Giselle Villar, CDM Smith

8th Annual NASTT-SC Texas/Oklahoma

CUIRE hosted the 8th annual South Central NASTT Trenchless Technology and Pipe Conference (TTP 2024), Aug. 12 to 13 at the University of Texas at Arlington. This conference included technical sessions divided into three tracks: rehabilitation, new installation and trenchless planning. Presenters include industry representatives, professors, and university researchers.

Track A: Rehabilitation

- Mike Larsen, Structural Technologies

- John Newell, President NoDigTec, LLC

- Jacob Brumbaugh, P.E., RJN Group, Inc.

- Justin Mouton and Ted Jones, P.E, Henkel Corporation

- Nely Rezaei, P.E., city of Lewisville and Timothy Peterie, Azuria Water Solutions

- Alan Goodman, Hammer Head Trenchless

- Amanda Powers, P.E., Brian Glynn, PE, Todd Reck, P.E., Steve Pettit, P.E. and Robert Sauceda, P.E., Freese & Nichols Inc

- Diego Medrano and Michael Salinas, P.E., Garver

- Timothy Palmer, Wade Trim - Dallas

Track B: New Installation

- Robert Weinert, Plummer

- Rami Issa, P.E., AECOM and Rishi Bhattarai, P.E., Dallas Water Utilities

- Justin Taylor P.E. and Gunnar Busch, P.E., CCI & Associates, Damola Ashaye, P.E., Azuria Water Solutions

- Kyle Krueger, P.E. and Carl Craigo, P.E., Parkhill

- Chase Juhl, P.E., Corey Evans, P.E. and Sergio Flores, P.E., Black & Veatch

- Madhab Sharma Bajgain, Brian Glynn, P.E., Mears Group, Inc., Direct Pipe & HDD Division

- Landon Allen, Parkhill, Inc.

- Tracey Long, P.E., Rishi Bhattarai, P.E. and Neepa Shah, P.E., Dallas Water Utilities

- Karina Diaz, EIT, Michael Salinas, PE and Maureen Carlin, Garver

Track C: Trenchless Planning

- Justin Taylor, P.E. and Gunnar Busch, P.E., CCI & Associates Inc.

- David Paul Bearden, HDR

- Shima Zare, Dr. Mo Najafi, P.E. and Rasoul Adnan Abbas, CUIRE

- Eric Toffin, Metallic Pipeline Solutions

- Dr Vinayak Kaushal, P.E., University of Texas at Arlington

- Dr Arpita Bhatt, University of Texas at Arlington

- Milton Brooks, P.E. and Todd Woodson, P.E., Dallas Water Utilities

- JD Fuquay, Fuquay

- Chris Brooks, P.E., RJN Group, Inc.

Sponsors included

- Westlake Pipe and Fittings (Platinum)

- Insituform – Aegion (Gold & Lanyard)

- Uni-Bell PVC Pipe Association - Corporate HQ (Gold)

- Elgin Separation Solutions (Gold)

- CPM Pipelines (Gold)

- Thompson Pipe Group (Gold)

- Parkhill (Silver)

- Ace Pipe Cleaning, Inc. (Silver)

- KOPPL Pipeline Services, Inc. (Silver)

- Core & Main (Silver)

- Wade Trim (Silver & Coffee)

- Horseshoe Construction, Inc. (Bag & USB)

Recognizing CUIRE Ph.D. Students

Ehsan Rajaie, a Ph.D. candidate at the University of Texas at Arlington (UTA) and an infrastructure engineering assistant at the Tarrant Regional Water District (TRWD), has been awarded the esteemed 2024 Scholarship by the American Water Works Association (AWWA). Selected from over 800 applicants, from the US and Canada, this accolade is a significant milestone in his academic and professional journey.

With 14 years of experience in the civil engineering industry, Ehsan has honed his expertise in research, design, inspection, and construction management. His current research at CUIRE, under the supervision of Dr. Mo Najafi, focuses on trenchless technology methods for pipe rehabilitation and renewals, as well as developing structural methodology using the Finite Element Method (FEM).

Ehsan has actively contributed to the infrastructure engineering field, presenting at renowned conferences such as NASTT and UESI. He has also shown excellence in his academic career by earning numerous scholarships and awards from organizations such as AWWA, NASSCO, CMAA, NASTT, UCA, and ASCE. Ehsan’s achievement highlights his dedication to creating impactful civil engineering infrastructure, particularly in pipeline rehabilitation and water infrastructure.

CUIRE Recent Graduates

Sanaz Ghalambor, Ph.D. with a civil and polymer engineering background, is working as an advisory engineer – Spray-in-place Lining Solutions at Framatome. She obtained her Ph.D. in civil engineering, from the University of Texas in Arlington in August 2023 for her work on spray-applied polymeric lining selection, evaluation, and design in pipe rehabilitation projects.

Dr. Ghalambor graduated in polymer engineering from the Polytechnic University of Technology and an MBA from CUI. Dr. Ghalambor has over two decades of experience in polymeric coatings and linings, pipeline integrity, corrosion prevention, and pipe rehabilitation and has had several papers and presentations at UCT, NASTT, ASCE, and IWA. She has worked in oil and gas, and water/wastewater industries and has joined Framatome since 2023.

Kawalpreet Kaur graduated with a Ph.D. in Civil Engineering from the University of Texas at Arlington (UTA) in August 2023. She earned her master’s in construction engineering and management from San Diego State University. She received scholarships from CMAA, NASTT and WTS during her academic career. Dr. Kaur received the Outstanding Ph.D. student Award for 2022 and 2023 from the Civil Engineering Department at UTA.

She is currently a postdoctoral research associate focusing on trenchless technology, pipeline rehabilitation and asset management. Her research focuses on designing, testing, and evaluating SAPL. She is also working on developing test procedures and product evaluations for stormwater storage and infiltration chambers, as well as modules. She conducts various experimental tests to assess material suitability for field applications. Dr. Kaur has presented at conferences such as NASTT, UESI, CUIRE Schools and UIC.

Zahra Borhani

Zahra Borhani graduated from the University of Texas at Arlington with a master’s degree in construction management in August 2023. As a program manager and research assistant at CUIRE, some of her notable achievements include serving as a president of the Student Chapter of NASTT. Borhani had contributed to a proposal writing for a total of $710,000 competitive grant from the WRF. She had secured a total of $20,000 in funding to support NASTT-SC members' attendance at conferences.

Borhani received student scholarship awards from NASTT and CUIRE. She has organized and hosted conferences such as the CUIRE/UCT Schools 2023 in Orlando, Fla.; UESI Conferences 2022 and 2023 in Arlington, Texas; and Trenchless Technology Conference 2022 in Arlington, Texas.

Saeed Asadi graduated with a Master of Construction Management from the University of Texas at Arlington in May 2024. He had the privilege of serving as a Graduate Teaching Assistant for courses such as Construction Engineering, Introduction to Civil Engineering, and Construction Contracts, Specifications, and Administration. During his studies, he was actively engaged in academic and research activities with CUIRE.

Asadi’s involvement extended beyond the classroom, including the valuable experience of participating in the NASTT No-Dig 2024 conference in Rhode Island with the CUIRE team. These experiences have not only enriched his academic journey but have also prepared him for a dynamic career in the construction management field.

Hajar Naeini graduated with a Master of Construction Management from the University of Texas at Arlington in May 2024. She has a Master of Architecture from the Art University of Isfahan, where she gained a unique blend of architectural background and construction management expertise.

Throughout her studies, she served as an instructor for a computer-based design application course at UTA for two years, leveraging several years of teaching experience. Her academic journey included active participation with CUIRE, and she participated at the NASTT No-Dig Shows in Portland in 2023 and Rhode Island in 2024, gaining invaluable exposure to cutting-edge trenchless technologies.

She was awarded tuition waivers for all four semesters of her master’s degree and received the Engineering Gold Star Graduate Scholarship. Additionally, her internship at Mart has further refined her project management skills. These experiences have equipped her with a comprehensive understanding of the construction industry, preparing me for a dynamic and impactful career.

A May 2024 graduate, Talayeh Bahrkazemi is a project engineer at Southland Holdings, in Dallas, Texas. She has a dual master’s degrees in construction management and urban design, complemented by practical experience in architectural engineering with skills in project planning, and coordination.

She utilizes Building Information Modeling (BIM) to model and coordinate various aspects of construction projects, ensuring accurate design integration and efficient project management.

Dr. Madhuri Arjun is an assistant professor of instruction in the Civil Engineering department at the University of Texas at Arlington (UTA). She served as an adjunct professor during her Ph.D. program. She has an MS degree in Structural Engineering and has worked on seismic engineering projects at Sungkyunkwan University, South Korea. She has 10 years of experience in construction management, structural design, research, and teaching.

Currently, Dr. Arjun teaches various undergraduate courses in construction engineering and management, and general civil engineering. She has authored more than 16 peer-reviewed conference papers. She has been actively involved in industry research projects on sustainable trenchless pipeline construction and renewal technology and has collaborated at CUIRE to write several research proposals.

She has served as a paper reviewer and moderator in the ASCE-UESI Pipelines Conference in 2023 and 2024. Dr. Arjun's doctoral dissertation focuses on the development of a prediction model to prioritize sewer inspections by adopting the latest AI-based machine learning algorithms.

Comments