August 2023 Vol. 78 No. 8

Features

Currently at CUIRE – Annual update of research center’s activities

Classification, Certification Requirements for Polymeric Spray-Applied Pipe Lining for Gravity, Pressure Pipes

(UI) — Pipe deterioration is a complex process, involving a combination of aging, chemical and environmental factors.

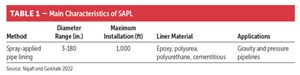

The trenchless technology renewal method of spray-applied pipe lining (SAPL) is one of the most cost-effective and sustainable methods, with minimum ground disturbance. This method provides an effective solution for improving the deteriorated condition of culverts and pipelines to enhance their design life (TABLE 1).

In addition, SAPL provides a monolithic layer that prevents further deterioration of pipes (Najafi, 2022). The materials used for SAPL fall within two broad categories: cementitious and polymeric. Cementitious products are categorized as rigid, and polymeric materials – including polyurea, polyurethane, and epoxy – are categorized as flexible.

The polymeric liner has a thermoset material characteristic. TABLE 1 depicts the main characteristics of SAPL.

Polymeric SAPL is a new application to structurally renew deteriorated gravity and pressure pipelines and can be applied to a wide range of concrete, masonry, corrugated metal, and steel pipelines. Furthermore, polymeric lining is approved for water mains by the National Sanitation Foundation (NSF) (Najafi, 2022).

SAPL can be applied manually or with robotic application, depending on the pipe diameter and space constraints. FIGURE 1, below, shows manual and robotic application of the SAPL liner.

SAPL has material characteristics that can be applied for corrosion protection and/or to increase the load bearing capacity of the host pipe. The potential application of SAPL as a fully structural renewal process has been tested for culverts and drainage structures by the Center for Underground Infrastructure Research and Education (CUIRE) at the University of Texas-Arlington, but it is still underway for pressure pipeline rehabilitation.

This article focuses on the testing requirement for applying polymeric SAPL in gravity and pressure pipes.

Currently, manufacturers and contractors are implementing design methodologies for SAPL applications from other available methods, such as ASTM F1216- Standard Practice for rehabilitation of existing pipelines and conduits by the inversion and curing of a resin-impregnated tube, and ASTM F1743 Standard Practice for rehabilitation of existing pipelines and conduits by pulled-in-place installation of cured-in-place thermosetting resin pipe (CIPP).

The lack of comprehensive standards, design guidelines, testing and evaluation of SAPL is limiting its acceptance and use by DOTs and private entities to renew old pipes. Thus, sufficient information is not available to confirm SAPL as a structural and durable renewal technology to enhance the expected lifespan of gravity and pressure pipeline.

Because of the need for sufficient information on this technology, CUIRE, in collaboration with various industries, is testing and evaluating the structural properties of polymeric SAPL for gravity and pressure pipes. Researchers are continuously developing testing programs to review and certify the use of SAPL material in pressure pipes based on different AWWA structural lining classifications described later in this article.

To achieve this objective, the article will suggest some testing and methodologies for the classification and certification requirements for polymeric SAPL for gravity and pressure pipes.

Structural lining classification

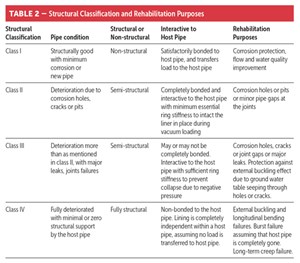

As per AWWA Structural Classification of Lining Systems (2019), the SAPL lining system is divided into Class I, II, III and IV. TABLE 2 shows a general and broad spectrum for the host pipe condition and the suggested liner classification design, according to the AWWA structural classification.

Testing, certification for polymeric SAPL

Polymeric lining system testing can be categorized into three types:

- material properties testing

- gravity pipes full-scale laboratory testing

- pressure pipes short-term and long-term full-scale laboratory testing

Material properties testing is required to determine the mechanical properties of the material, which can be useful in designing the liner material for its application in different host pipe and environmental conditions. Material properties of the liner are required to design lining systems both in gravity and pressure pipes. TABLE 3 presents the suggested material properties tests for the polymeric material, along with their significance in the lining system application.

TABLE 3 includes both short- and long-term material testing. Material testing such as flexural, tensile and punch shear tests are commonly performed on the polymeric material to determine the tensile and flexural strength and modulus of elasticity.

In addition, the long-term creep properties of the material, both tensile and flexural, are important to determine the material behavior under long-term loads, which are required for semi-structural and structural design of liner systems for pressure and gravity pipelines.

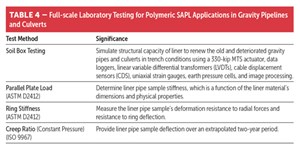

Full-scale laboratory testing: gravity pipelines and culverts methods are represented in TABLE 4 represents the full-scale laboratory test methods for gravity pipeline applications.

CUIRE has performed full-scale laboratory soil box testing on lined and unlined corrugated metal pipes and investigated the structural integrity of the liner. In addition, the parallel plate test is recommended to determine the pipe stiffness and deformation resistance against radial forces and ring deflection. The creep ratio test will be useful to determine the long-term deflection of liner over time under constant pressure.

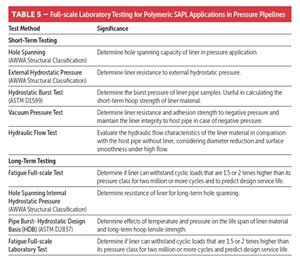

Full-scale laboratory testing: pressure pipelines – TABLE 5 presents the full-scale laboratory test methods for pressure pipeline applications. The recommended testing is categorized into two types: short-term and long-term.

Many researchers have been working on the testing and certification of the liner material in pressure pipes application for different structural classifications. However, the liner has been certified up to Class III in pressure pipes application, and the Class IV certification is still in progress.

Short-term full-scale laboratory testing

TABLE 5 presents suggested tests that can be performed on SAPLs to certify and classify them as Class II, III, or IV and use it to renew the pressure pipelines. Short-term testing determines the resistance of a liner in a short time span.

Short-term hole spanning testing was performed by CUIRE for a 30-inch diameter host pipe with hole-spanning sizes of 0.5, 1, 2, 4, and 6 inches. The pipe samples with 0.5-, 1- and 2-inch hole spanning sizes were lined with pure polyurea elastomeric material, and the lining system passed 500 psi pressure without failure. The 4- and 6-inch holes spanning testing is still in progress.

In addition, CUIRE is working on the short-term external buckling test to determine the liner resistance against the buckling effect due to external hydrostatic pressure. Both the short-term hole spanning and external buckling tests, along with the vacuum pressure test, will confirm the liner structural properties, as per class II and III. FIGURE 2 shows the hole-spanning test setup in progress. FIGURE 3 represents the complete hole-spanning test set up with a hydrostatic pump assembly.

The short-term hydrostatic burst test is helpful to confirm the liner integrity, assuming the liner has no support from the host pipe, or the host pipe completely deteriorates. Liner pipe samples can be cast with the rig systems or sonotube and tested under a desired working pressure over a short period of time to determine the liner resistance, without the support of a host pipe. Burst pressure testing can be employed by the manufacturer to qualify the SAPL material under the defined pressure class, similar to the PVC pipe manufacturing industry.

Since the liner material applied to the host pipe decreases the internal pipe diameter, it is important to compare the hydraulic flow characteristics with flow characteristics of the host pipe without liner, noting the improved surface smoothness. This is an important consideration in pressure pipe relative to pumping needs.

Long-term full-scale laboratory testing

The tests presented in TABLE 5 are suggested tests that can be performed to determine the creep behavior of the liner over a longer period of time, i.e., approximately 10,000 hours in pressure pipe application. These tests will also be helpful for predicting the design life of the liner.

The long-term hole spanning internal hydrostatic pressure is similar to the short-term hole spanning test. The difference between the two tests is the period of time for which the pressure needs to be held. The test can determine the long-term capacity of the hole spanning at the desired hydraulic pressure.

The long-term pipe burst hydrostatic design basis test can be performed for 10,000 hours. The data obtained from this test can be used to extrapolate 50 years of design life of the liner. Fatigue full-scale laboratory tests can be performed on the liner pipe samples and provide loading to the pipe samples for the desired number of cycles.

Pipelines subjected to cyclic stresses weaken more rapidly than those operating under steady pressure. Hydraulic pressure surges, transients and water hammers are important considerations for SAPL design in water transmission and distribution systems relative to fatigue behavior of the liner. Results from fatigue testing determine if the liner can withstand cyclic loads that are 1.5 or 2 times higher than its pressure class for 2 million or more cycles, as well as predict design service life.

This article presented the testing requirements needed for the evaluation and certification of polymeric SAPL in gravity and pressure pipe applications. It can help partitioners use different test methods and certify the polymeric SAPL in different field conditions, as per structural classification for the renewal of gravity and pressure pipes application.

Since there is not enough testing and research done on the SAPL for structural capabilities, practitioners have limited confidence in using the SAPL material as a structural material in pressure pipes. Material testing is key to understanding the material’s properties and its behavior in different fields and environmental conditions. In addition, having these properties gives a more reliable design of the liner system for both pressure and gravity application.

Future plans include consideration of extreme temperature and environmental conditions during testing.

REFERENCES

Najafi, M. and Gokhale, S. (2022). Trenchless Technology. McGraw-Hill Education.

CUIRE Holds Annual Conferences

CUIRE held its 21st annual trenchless technology inspector training and certification schools on Monday, Feb. 6, in Orlando Convention Center, Fla., in conjunction with the Underground Construction Technology Conference.

This year’s program included one-day of the Advanced HDD School and Pipe School. In addition, a half-day Pilot Tube and Microtunneling School and Spray Applied Pipe Lining School were offered. More than 35 professionals attended these courses. The instructors were industry experts and included CUIRE board members and friends.

The next CUIRE Schools will be in conjunction with Underground Infrastructure Conference (formerly UCT) on Monday, March 18, 2024, at the Oklahoma City Convention Center.

CUIRE Schools Speakers were:

Advanced Horizontal Directional Drilling Schools:

- Jeff Puckett, P.E., president, J.D. Hair & Associates, Inc.

- Jwala Sharma, Ph.D., PE., project manager, Michels Corporation

- Mike Whitehouse, technical sales/fabrication specialist, ISCO Industries, Inc.

- Peyton Boyle, Vermeer Corporation

- Jim Williams, PE, PMP, senior associate, Brierley Associates

- Mark Gallucci, customer insight, Digital Control Incorporated

Pipe Schools:

- Jeff Boschert, P.E., National Clay Pipe Institute

- Rich Mielke, P.E., Northwest Pipe

- Allen Cox, DIPRA regional director

- Shah Rahman, MBA, practice leader – North Texas, KCI Technologies Inc.

- Brad King, Underground Solutions, Inc.

- Rene Garcia, HOBAS Pipe USA

- Camille George Rubeiz, P.E., Plastic Pipe Institute

Pilot Tube and Microtunneling School:

- Troy Stokes, Akkerman, Inc.

- Jeff Boschert, National Clay Pipe Institute

- Dr. Glenn M. Boyce, Ph.D., PE, McMillen Jacobs Associates

Spray Applied Pipe Lining (SAPL) School:

- Sanaz Ghalambor, polymer engineer, Nukote Coating Systems International

- Dr. Mo Ehsani, PhD, PE, SE, QuakeWrap Inc.

- Kawalpreet Kaur, research associate, CUIRE/UTA

- Dr. Amin Tehrani, project manager, Freese and Nichols

- Dr. Zahra (Ellie) Kohankar, project engineer, ASFI

4th Annual UESI Conference

On July 26–27, 2023, CUIRE teamed up with the Texas Chapter of the Utility Engineering and Surveying Institute (UESI) of ASCE to hold its 4th annual UESI conference in Texas. More than 150 professionals, in addition to 30 exhibitors and 18 sponsors, attended this conference.

Sessions were divided into three tracks of Utility Engineering, Specialization I and II, and Surveying. A reception was held on the evening of July 26 at the exhibit hall and more than 60 people attended this event.

Upon completion of the above events, attendees received a certificate of completion and a PDF copy of all presentations. For more information on future events, call CUIRE at (817) 272-9177 or email cuire@uta.edu or visit www.cuire.org.

Innovative Technologies for Monitoring Water Assets

A University of Texas at Arlington (UTA) civil engineering researcher is leading a nationwide study to find and assess innovative technologies for monitoring water assets.

Mohammad Najafi, a UTA associate professor of civil engineering, is leading a $410,000 grant from the Water Research Foundation.

Other water entities participating in the funding and project include: DC Water, Los Angeles County Sanitation Districts, CDM Smith, Dallas Water Utilities, Greater Cincinnati Water Works, Dallas County, Tarrant Regional Water District, WaterOne, American Water, WSSC Water, The Great Lakes Water Authority, Orange County Utilities, San Diego County Water Authority and Underground Infrastructure.

“We hope to streamline water asset monitoring so water utilities can make timely decisions and optimize their maintenance activities,” Najafi said. “We will investigate the utilization of existing and innovative asset monitoring technologies, such as drones, sensors, fiber optics, etc., for both horizontal and vertical assets. Considerations for both large and small water utilities will be given.”

The project will perform a comprehensive literature review on the topic, hold conferences and webinars among water utilities and industry leaders, provide case studies of what is available, and make recommendations and guidelines on what to use in the future.

Najafi said the project will identify gaps in water utility monitoring and make recommendations to fill those gaps.

“Water monitoring now consists of using sensors, drones, fiber optics, advanced metering infrastructure and other technologies that are on the market and currently being used, but not by everyone,” Najafi said. “We hope to issue a best practices guideline for water entities.”

The project will look at above-ground water infrastructure, like reservoirs and dams, as well as below-ground infrastructure like pipes and mains.

Melanie Sattler, interim chair of the UTA Department of Civil Engineering, said Najafi’s project will give water entities better information now and in the future.

“Water monitoring is essential to provide the resources needed for life and growth,” Sattler said. “This project does just that. Knowing how much water you have is vital to knowing how much water you’ll need in the future.”

Najafi is also director of UTA’s Center for Underground Infrastructure Research and Education (CUIRE), where much of his research takes place.

CUIRE is a research, education and outreach organization and is a part of UT Arlington’s Department of Civil Engineering. Since its inception, CUIRE has focused on assembling exceptional and broad-reaching engineering and technical talent to address the needs of underground infrastructure on a regional, state, national and international scale.

Vinayak Kaushal, a UTA assistant professor of civil engineering, will serve as co-principal investigator. Zahra Borhani, program manager at CUIRE, and Diego Calderon, a doctoral candidate, are part of the UT Arlington team for this project.

CUIRE Graduate Students Receive Scholarships

Ehsan Rajaie is a Ph.D. student in Civil Engineering with a research area in developing structural design methodology for spray-applied pipe linings (SAPLs).

- NASSCO’s Jeffrey D. Ralston Memorial 2023 Scholarship

- ASCE/UESI Student 2023 Scholarship

- Construction Management Association of America (CMAA)

- North Texas Chapter 2022 and 2023 Scholarships

- SME 2022 and 2023 Scholarships

- NASTT South Central Chapter 2022 Scholarship

- APWA - Texas Chapter 2022 Scholarship

- Outstanding Civil Engineering Ph.D. Student Award

Kawalpreet Kaur is a Ph.D. candidate in civil engineering with a research focus on designing, testing, and evaluating spray-applied pipe lining (SAPL) for gravity and pressure pipe applications. She is also serving as vice-president of the NASTT-UTA student chapter.

- WTS Dallas/Fort Worth Chapter 2023 Scholarship

- NASTT South Central Chapter 2021 and 2022 Scholarships

- ASCE’s UESI Student 2022 Scholarship

- Construction Management Association of America (CMAA)

- North Texas Chapter 2022 and 2023 Scholarships

- Outstanding Civil Engineering Ph.D. Student Award

Madhuri Arjun is a Ph.D. candidate in civil engineering with a research area in the condition assessment of sewer pipelines using machine learning.

- NASTT South Central Chapter 2022 Scholarship

- NASTT South Central Chapter 2022

- ASCE’s UESI Student 2023 Scholarship

- Civil Engineering Ph.D. Student Scholarship 2022

Industry Partnership to Test Underground Stormwater Storage, Infiltration Infrastructure

A University of Texas at Arlington (UTA) faculty member and Xerxes Corp., a leading innovator in composite chamber and tank engineering, will collaborate to create test procedures and product evaluations for stormwater storage, infiltration chambers and modules.

UTA Civil Engineering Associate Professor Mohammad Najafi is working with Xerxes on material and full-scale in-ground product evaluations as part of a $207,495 project to determine how well the equipment can withstand vehicle and soil loads under various real-life design scenarios.

“We’re testing these products, which are designed for use under trafficked areas, with both shallow-cover, short-term, high-load applications, as well as deep-cover, long-term earth loads,” Najafi said. “We’ll take advantage of a lab-like controlled environment to apply different load scenarios on a number of chamber and module tank designs with and without features, like inspection and connection pipes.”

Long-term loading tests will also be performed to assess small responses to earth loads typical of deep installations.

“We’ll check durability by loading the equivalent of highway traffic on them and up to 26 feet of cover. We need to determine how best to design for many different and complicated load scenarios,” Najafi said. “This project aims to do just that by leveraging existing test standards and our experience from other underground research projects.”

Najafi said the chambers will be tested following all applicable American Society for Testing and Materials and American Association of Highway and Transportation Officials standards.

“What makes this testing so distinctive is the ability to simulate real-world loads on full-scale, commercially available products in actual field-installed conditions,” he stressed. “It will be like lab-testing the effects of heavy truck loads on the chambers and modules with full control of the test environment, but in the field. Our soil box laboratory and hydraulic actuator by MTS Systems can do that.”

The entire project will be conducted in the Center for Underground Infrastructure Research & Education (CUIRE) lab, which is managed by Najafi. CUIRE is a research, education and outreach organization and part of UT Arlington’s Department of Civil Engineering.

Since its inception, CUIRE has focused on assembling exceptional and broad-reaching engineering and technical talent to address the needs of underground infrastructure on regional, state, national and international scales.

Najafi is well-known internationally for his research and publications in underground infrastructure. Melanie Sattler, interim chair of the UTA Department of Civil Engineering, said Najafi’s work is integral to the functionality of the country’s infrastructure system.

“It’s always important for our department, our college and our university to partner with the private sector like Xerxes whenever we can,” she said. “We believe these collaborations are essential to a thriving industry and, more importantly, the country’s infrastructure.”

Kawalpreet Kaur | Research assistant, CUIRE, Department of Civil Engineering, University of Texas at Arlington

Sanaz Ghalambor | Researcher, polymer engineer, Nukote Coating Systems International, LLC

Mohammad Najafi | Ph.D., P.E., F.ASCE, professor/director, CUIRE, Department of Civil Engineering, UTA

Diego R. Calderón | P.E., M.ASCE, Research Assistants, CUIRE, Department of Civil Engineering, UTA

Comments