December 2022 Vol. 77 No. 12

Rehab News

Rehab Technology: Tips for Using Bypass Pipe Plugs for Sewage Bypass

Pete Rogers, Cherne Industries

(UI) — Pipe plugs are designed to perform three essential functions: blocking a pipeline, conducting an air test in a pipeline, and bypassing effluent in an active pipeline.

Blocking a pipeline becomes necessary during new installation or maintenance, when effluent needs to be temporarily stopped or a new pipe is air tested for leaks.

Air testing is conducted in a new installation, before placing a pipeline in service, or when trying to locate a leak in an existing line.

Bypassing is necessary when the flow of effluent in a pipeline needs to be redirected, usually to perform maintenance or repair for a longer period of time, when the flow cannot be stopped.

This article concerns sewage bypass and selecting and using bypass plugs.

A bypass plug has a tube or hose that’s open at both ends and runns entirely through the plug. Most bypass plugs come with caps threaded onto the bypass on the front of the plug.

Cherne’s bypass plugs, called Muni Balls because they are primarily used in municipal sewers, are versatile. With the cap on, the plug can be used for blocking; with the cap removed, it can be used for bypassing. In addition, when the cap is adapted with air fittings, it can be used to perform an air test.

Muni Balls are available from three-quarters to 96 inches in diameter, with bypass tubes ranging from a half inch to 24 inches.

Types of bypassing

Bypass plugs are typically designed for two types of bypassing: pump and gravity.

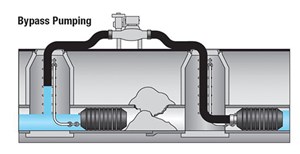

Pump bypassing involves installing a Muni Ball in a pipeline upstream from where maintenance or replacement work needs to be conducted. The plug is installed into the pipe, and a hose or pipe is attached to the bypass on the front of the plug. The hose is then connected to a pump on the intake side and another on the output side.

Then, effluent is pumped up and out of the manhole, running downstream and past where the work is being conducted, before it is routed back into another manhole where the effluent can continue. A blocking plug is installed on the upstream side of this manhole to prevent effluent back from flowing toward the work area.

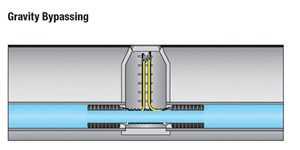

Gravity bypassing occurs when work needs to be conducted in an active manhole, but the flow cannot be blocked. In this instance, two Muni Balls are installed into both access pipes that feed into the manhole. A hose is connected between the bypasses of the two plugs so the flow can continue while the manhole remains dry.

Proper bypass plug selection

To select the correct bypass plug (or Muni Ball) for an application, the following questions need to be answered:

- What is the inside diameter of the pipe you need to plug?

- How much volume must the bypass accommodate? This impacts the size of the bypass required. You can obtain this information from your project engineer.

- What are the back pressure requirements? In other words, how much pressure will the plug be required to hold? (Pressure is most commonly measured by either pound per square inch, when the pressure is coming from air; or feet of head, if the pressure comes from liquid such as water or sewage.

- What is the access opening the plug needs to fit through to be installed? Most commonly, this would be the diameter of the manhole the plug must be passed through before it is installed. Many Muni Balls have flexible hose bypasses that allow the plug to be bent up to 45 degrees to aid in installation.

- What is the temperature of the media being blocked? Natural rubber should not be exposed to temperatures exceeding 125 degrees Fahrenheit, as it will begin to melt.

- Will there be any oils, hydrocarbons, or petrochemicals in the media that needs to be blocked? These may harm natural rubber and cause it to degrade. Please consult with the factory if your application involves blocking such substances.

Special care needs to be taken before and after a Muni Ball, or any pneumatic plug, is placed into service:

- Inspect the rubber body of the plug for punctures, bulges, cracks, corrosion, and leaks.

- Inspect the end plates of the plug for cracks, loose fit, missing or damaged eyebolts, rusty end plates and fittings, and damaged inflation fittings.

If any of these appear, we recommend consulting the Cherne, or other manufacturer, factory.

Plug installation

While installing a bypass plug:

- Make sure an extension hose with an accurate pressure gauge is used to safely inflate the plug, monitor its air pressure while in use, and deflate the plug from a safe distance.

- Always ensure the pipe the plug is being installed in is inspected and debris, such as gravel or broken glass, is removed.

- Avoid installing the plug over any exposed rebar.

- Ensure the plug is inflated to the exact inflation pressure prescribed by the manufacturer.

After the work is completed, eliminate any back pressure in the pipe before deflating the plug. Do not attempt to remove the plug from the pipeline until it has been completely deflated.

Most damage occurs to plugs when they are either being installed or removed from the pipe. A safety instruction manual is provided with each Muni Ball when it leaves the factory. Make sure you review it and understand all precautions.

A safe pipe plug usage video is available online at Cherne Product Safety Video–YouTube

ABOUT THE AUTHOR: Pete Rogers is an inside sales specialist at Cherne Industries (part of the Oatey family of companies). He has been with Oatey Co. for more than 50 years. He can be reached at chernesupport@oatey.com.

FOR MORE INFORMATION

Cherne, (800)-843-7584, oatey.com

Comments