July 2020 Vol. 75 No. 7

Features

Trenchless Technology Center Report: Diverse TTC Programs Provide Industry Benefits

By Dr. John Matthews, Trenchless Technology Center Director

The Trenchless Technology Center (TTC) at Louisiana Tech University once again had an active year of research, training and growth, with its Industry Advisory Board (IAB) continuing to meet its mission to advance trenchless technology by serving as an independent source of knowledge, research and education in the industry.

Not immune to recent impacts of the global pandemic that has affected all aspects of our daily lives, TTC has been operating remotely, but critical research tasks have taken place on-campus, as needed to meet the objectives of our clients and partners. We are expecting to be back on campus full-time by the fall semester.

TTC has maintained its role as a leader in trenchless education and research, and increased its influence in the areas of industry workforce development and training. This was highlighted by growth in the number of overall researchers in the center this year, with the addition of two post-doctorate students and a research associate.

We again reached new heights in the overall number of IAB members, as we entered our 31st year of existence. This tells us that our mission is valuable to trenchless technology manufacturers, contractors, engineers and owners.

Research and development

Reflecting active and diverse research contracts, a number of industry and governmental projects are taking place and even more proposals are being submitted to a wide range of funding agencies. As has been the case historically, the majority of TTC research continues to be funded by industry clients and associations, some of whom require various types of non-disclosure agreements (NDAs), which limits the amount of research TTC is able to publish.

Despite this fact, researchers produced a record-setting 14 peer-reviewed journal papers in 2018 and exceeded that amount with 17 in 2019. So far, 2020 is off to a great start and TTC expects to exceed the record set last year.

Currently, more than 10 active research projects are underway, Updates on some of these efforts are noted below.

CIPP Emissions Study

A team led by Dr. Elizabeth Matthews, assistant professor of civil engineering, completed the CIPP emissions study for NASSCO. This project included field data collection at more than six installation sites to determine the impact of steam-cured CIPP on workers and the environment.

Some key findings were that the only potential exposure to dangerous levels of styrene – the only VOC detected at elevated level – was at the opening of the liner transport truck door and near the exhaust point. Of note is that the styrene levels that were measured near the exhaust points were consistently lower than the data published by some researchers that claimed to have measured much higher levels.

This calls into question those previously published higher levels, which actually led to this study, as there have been several other studies in the past with results more closely aligned with the TTC study. The full report is available at www.nassco.org.

Non-destructive Testing Technology

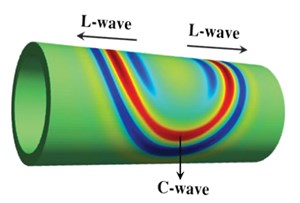

TTC continued to be a thought leader in the area of non-destructive testing (NDT) technology and its application, through areas led by Dr. Arun Jaganathan, associate professor of civil engineering.

For years, this work has been applied to solve problems related to in-pipe inspection, wall defect detection, obstacle detection and avoidance. Most of the work is carried out completely in-house, from theoretical modeling, to design and prototype solutions. In fact, most of the modeling is written in unique code, not with commercially available software programs (see “NDT Modeling” image).

This is a unique capability, even for a university research center, that TTC is able to share with its trenchless partners to help solve complex problems. Most of the TTC work in this area cannot be published due to NDAs and Intellectual Property protections, but TTC recently proposed a large federal grant to apply these capabilities to oil and gas pipeline assessment and quality assurance of repairs.

Innovative Materials

TTC continued its internally funded work this year in the area of innovative materials led by Dr. Shaurav Alam, TTC associate director of research. Alam’s team has been investigating numerous thrusts, including innovative cementitious materials for infrastructure components and coatings, as well as innovative curing of construction materials and pipe lining materials. The findings are fascinating and have potentially wide-spread impacts for the construction industry.

Additionally, Research Associate Dr. Omar Abdulkareem, has been leading internally funded work in fiber-reinforced advanced construction materials. This work was recently awarded a state grant to further its application for pipe repair. Research Scientist Dr. Amin Azimi has been leading TTC woin the development of advanced pipe installation technology. The first phase has been completed with our industry partner and we are now collaborating on developing a second phase.

Continuing its work with various trenchless rehabilitation technology suppliers to further develop testing methods and protocols for innovative materials and designs, TTC pursued and obtained lab accreditation to ISO/IEC Standard 17025:2017. This achievement took a team effort and was not a straightforward process. This is due to the cutting-edge nature of several of the materials/methods in the trenchless industry, for which standard tests do not yet exist.

Despite this fact, TTC was able to meet ISO 17-025 standards and has the ability to add more tests to its accreditation in

the future, if needed. Special thanks go to Chris Morgan, lab manager, along with Drs. Alam, Azimi, and Abdulkareem, for their support in this effort.

NSF Research

A final research note is that the highly competitive National Science Foundation (NSF) Industry/University Collaborative Research Center (I/UCRC) planning grant awarded to researchers at TTC and its partners at LSU, is coming to an end. The I/UCRC program is a unique offering from NSF that focuses on pre-competitive research, while also engaging directly with industry to ensure that research will have practical impacts down the road.

The center will be known as The Center for Innovations in Structural Integrity Assurance (CISIA) and will focus on a variety of related issues, including sensing, inspection, testing, analysis, and prediction. The CISIA team is planning to submit a Phase 1 grant proposal in the

fall and is still accepting industry partners to join this new NSF center.

Industry Advisory Board

One of the greatest strengths of TTC is its very active Industry Advisory Board (IAB), which has been in place since the center’s inception more than 30 years ago. A unique feature for a university research center, IAB both helps keep the staff focused on industry issues, and also provides workforce opportunities for many of the undergraduate and graduate students associated with the center.

TTC relies on the IAB for guidance on its activities and for financial support of the center and its research, which are key to the successful operation of its mission. This year, TTC increased IAB membership to a record number of 56 members –

five more than last year’s record.

IAB is bolstered by more than 20 municipal/utility members that support TTC in multiple ways, such as providing data for research and sites for field work when needed. Member organizations are listed below by category. For more information, please visit www.ttc.latech.edu.

Manufacturers & Contractors

Aegion, AOC Aliancys, BASF, BRH-Garver, CS-NRI/Geotree, Interplastic, IPEX, Reline America, Sanexen, SIPP Tech, and Trinity Products.

Municipal & Utility

Albany, NY; Aurora, CO; Bloomington, MN; Boston; Caddo Levee, LA; Citizens Energy (IN); Columbus, OH; Denver, CO; Houston; Hull. MA); Long Beach, CA; Los Angeles; Metro Wastewater Reclamation (CO), Monroe, LA; New York City; Portland, OR; Ruston, LA; San Antonio, Shreveport, LA; Tianjin (China), Upper Trinity Regional Water (TX), and Vancouver, WA

Chair: Tom Wynne, City of New York DEP

Vice-Chair: Ali Mustapha, P.E., Executive Director, Caddo Level District, Shreveport, LA

Consultants: Carollo, Garver, GeoEngineers, Jacobs, Kleinfelder, Stantec, and Subtegic

Media: Benjamin Media, Great Southern Press, and Underground Construction

Associations: LA CETF, NASSCO, and NUCA

Honorary: Joe Barsoom, Dr. Tom Iseley, Lynn Osborn, Kaleel Rahaim, and Dr. Ray Sterling.

TTC Sponsors: Olson Construction Law, QuakeWrap, Raven Lining Systems, SuperCover, and Thompson Pipe Group.

If you are interested in learning more about the IAB or joining the board, please contact TTC Director, Dr. John Matthews at matthews@latech.edu.

Municipal Forum Program Continues to Grow

The TTC Municipal Forum Program consisted of three forums during the fall 2019 season, with the three spring 2020 forums being canceled due to the pandemic. The attendance at the three forums totaled approximately 180 attendees and featured more 20 presentations from industry leaders.

Forum locations included Bossier City, La., Irving, Texas and Vancouver, Wash. The forums are designed as one-day programs with low participation costs and participants can earn continuing education units (CEUs) for attending.

We would like to thank the sponsors and speakers for all the 2019–2020 forums from the following organizations: Aegion, AOC Aliancys, AP/M Permaform, BLD Services, BRH-Garver, City of Portland, Ore., City of Shreveport La., CS-NRI/Geotree, Garver, HammerHead Trenchless, Interplastic Corporation, IPEX, Jacobs, Reline America, Subtegic Group, SuperCover and Thompson Pipe Group.

In addition to exploring online delivery, TTC is interested in new locations for these forums. If you are interested in hosting a forum or having specific topics included, or would like to present at any of the forums, please contact TTC Director Dr. John C. Matthews at matthews@latech.edu.

TTC Conducts 4th Utility Investigation School

The importance of accurately locating and depicting existing underground utilities becomes more obvious each day to ensure successful construction projects. It has been reported that at least 70 percent of projects experience delays and budget overruns due to utility conflicts. The Common Ground Alliance DIRT program reported in 2015 that there were 340,000 utility strikes and in 2017 this number grew to almost 380,000. The industry is experiencing too much property damage and loss of lives.

TTC has responded to this crisis by partnering once again with ASCE’s Utility Engineering and Surveying Institute (UESI) and the National Utility Contractors Association (NUCA) to offer a five-day Utility Investigation School (UIS). This specialty school was recently taught by the foremost experts in the geophysics and subsurface utility engineering (SUE) fields for the fourth time on Tech’s campus in early March. The course covered geophysics, utility systems construction and configuration, ASCE 38-02, risk-based presentations, and professional liability issues.

The instructors for this school were led Dr. Tom Iseley. The program included an industry day where technology providers were able to show and demonstrate their tools. The TTC team is committed to increasing the awareness and expanding knowledge of SUE on a global basis and

has also started to provide UIS schools at other locations.

BERT Training Facility

Currently, the TTC Underground Infrastructure Campus (UIC) consists of the world-class National Trenchless Technology Research Facility (NTTRF), sponsored by industry through the leadership of Dr. Ray Sterling, an LA Tech Professor Emeritus and Honorary TTC IAB member, during his tenure as TTC Director. In addition, TTC also has a facility used for long-term testing and specialized testing programs as well as specialized labs across LA Tech campus.

A new facility, Barbera Education, Research and Training (BERT), will be committed to meeting the ever-increasing challenges for the global underground infrastructure, Fund raising has met its initial goal and construction is expected to get underway this summer.

Once completed, TTC plans to begin using BERT right away by holding the fourth five-day Auger Boring School (ABS) this fall. Helping meet the high demand for engineers and contractors to have training in auger boring design, application and installation, ABS includes classroom lectures and practical sessions.

BERT will also be available for other training programs, and for international equipment and material manufacturers and technology providers to conduct research and development, and technology validation. The facility will also serve as the industry’s resource for workforce and professional development.

However, BERT is not the end of the story. This vision for TTC is to expand NTTRF to at least double its size and then construct a world-leading lecture hall with meeting rooms and offices totally dedicated to the trenchless industry.

For more information about training opportunities or any TTC research and other activities, please contact TTC Director, Dr. John Matthews at matthews@latech.edu. •

Comments