February 2020 Vol. 75 No. 2

Features

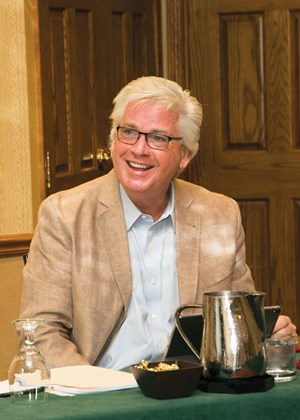

DCA President Mike Hickey Sees Bright Future for Contractors Who Embrace Change

By Jeff Awalt, Executive Editor

Mike Hickey still remembers the exact moment he first considered a career in underground construction. He was back in his native New York City after two years as a commercial diver offshore Louisiana, working for an old German American carpenter for $8 an hour and opening walls for Brooklyn Union Gas contractors to install shut-off valves.

As they approached a job site in pouring rain one day, Hickey looked out the window of the carpenter’s van and commented on the “poor guys” digging holes along the edge of the street. “Those ‘poor guys,’” old Hans replied, “are in a union, and they’re making $17 an hour.”

“That was a lot of money in 1980,” Hickey recalled. “So, I decided in a short time I was going to try to move on from carrying toolboxes and start digging holes.” He joined Kalb Construction that year, working his way up from laborer to foreman and, by 1984, supervisor, overseeing distribution gas service and main installations, until Kalb went out of business in 1988.

In 1990, Hickey and his three brothers went to work for Hallen Construction, New York City’s largest utility contractor.

Now executive vice president of Operations at Hallen, Hickey serves as a member of DCA’s Board of Directors and extends another proud tradition for Hallen this year as its fifth representative to serve as DCA President.

As local utilities run leaner and regulations grow in complexity and scope, Hickey sees an opportunity for distribution contractors to become increasingly valuable to the customers they serve – if they fully embrace the safety and other regulatory requirements engulfing the utility sector. He talked with Underground Construction before DCA’s annual convention, Feb. 24–29 in Boca Raton, Fla., about the opportunities and challenges facing distribution contractors and the approaches they can take to capitalize on these positive trends.

Family affair

UC: How did you and your brothers all go to work for Hallen at the same time?

Hickey: After Kalb went out of business in 1988, I bounced around the union for a little while, and then Hallen contacted us. Tom Poole and Bob Meschi hired us in April 1990. Tom Ryan, who was a part-owner of Kalb, and I were hired as supervisors. My brothers Terry and Gene, who also worked at Kalb, were hired as foremen. Our other brother Danny had been working in Manhattan but wanted to change fields, so they hired him as a laborer.

The contract they brought us in to run was one that we had worked on at Kalb. It was a type of work that Hallen really hadn’t done in many years, and they realized that we knew how to manage the contract.

UC: Is it unusual to have that many members of one family working in the business?

Hickey: Actually, the majority of our workforce has been brought in by people who worked at Hallen, whether it’s another family member or a friend and even through the unions, getting people from them.

We have three, fourth-generation employees currently working with us. We have probably a couple of dozen third generation and I would say somewhere in the neighborhood of 80 to 100 of our employees are second-generation employees.

My family is in the second generation – our father was a New York City detective, and our mother worked full time as a grammar-school secretary while raising the seven of us. My brothers and I were first, and then as our children and our three sisters’ children started coming of age, many of them started working for the company. I have two sons and eight nephews working for Hallen, so we have 10 in our second generation with the company.

UC: It sounds like you don’t have as much trouble attracting young workers to your company as many other DCA member companies have had.

Hickey: I know from talking with other members that it’s a serious issue, but we’re fortunate in that respect because our operations are very regional. One of the biggest challenges for many contractors with retaining young talent is that they operate over wide areas, and their employees spend long stretches away from home. We’re only in New York City tri-state area, which means that all of our people go home at night.

UC: What are some of the biggest changes you’ve seen in the industry from the time you started to the time your sons and nephews joined the company?

Hickey: I actually think the industry is heading in the right direction and it has been for quite a few years. I was cutting off gas services in my first week in the field. With no experience whatsoever. I was out there in sneakers and shorts and a T-shirt. We used garbage pails as barricades. But the safety and the qualifications and training have improved. It’s much safer and its more of a profession now than it was when I first started. It used to be just a job and now it’s a career. I guess that’s why we have so many college graduates that can’t get jobs are coming into our field, because we have dozens and dozens of college graduates who just couldn’t get jobs in other fields.

New and experienced mix

UC: How has it worked out for you at Hallen, mixing these young college graduates with your more experienced and traditional workers?

Hickey: It’s worked out well because we have a blend of some of the old timers like me that know how to physically do the work, and then you blend them in with the young and hungry kids coming in, and they teach each other.

A lot of the young people coming in now grew up with video games and video technology, where a lot of us didn’t have any of that obviously – it didn’t exist. When I first became a super in 1984, I had a beeper that just beeped and then you’d have to run find a payphone to call the dispatcher who would relay a message from the field. It was a big day when we got beepers that could actually tell you which number to call, it saved a lot of quarters.

As technology has come into the industry also, you have the old timers that are teaching the proper ways to do the jobs, teaching the techniques of doing the jobs. Plus, the young people coming in and bringing the technology into it and being able to handle all of the training and testing, and everything else that didn’t exist back when we all started in the industry.

UC: Training and operating procedures have also changed a lot since you started work in your shorts and sneakers.

Hickey: I had been in the industry almost 20 years when they came out with the first federal DOT operating qualification recommendations. It wasn’t regulations in the beginning – just recommendations. At that time, you’d just take a written test, and that was it. Now the testing portion of the qualifications is maybe 5 percent of the whole qualification program. It’s the final piece. But the training courses and the on-the-job training, and all of the tracking that goes on prior to passing that test are more critical than going into a classroom and taking a test. In fact, we don’t even go into classrooms here anymore, we go to Prometric sites.

UC: It’s common to hear people complain about increased industry regulations, but you seem to take a positive view of these changes.

Hickey: I actually think for contractors there are opportunities now that never existed before, because with all of the increased regulations that are coming on us and the criteria of workforce you have to follow, the utilities are going to become more and more dependent on us. But it requires a commitment to change.

The expression I’ve always used with our people is: We have two choices. We can change with it, or we get out of it. You can complicate it all you want, but it really is that simple. One of the great benefits to participating in DCA, attending meetings and sharing ideas, is that it gives you the ability to see what’s coming down the pike. It gives you the opportunity to choose to say,

OK, we know it’s going to happen. We can stay in front of these changes and start gearing our company to capitalize on them, or we can wait until the regulations are put into effect and then try to catch up.

Opportunities

UC: So, you see downsized utility companies and increasing demands as a growth opportunity for distribution contractors who stay in front of regulations?

Hickey: If a contractor is willing to adhere to the way the industry is changing, in my opinion, it’s going to open up opportunities for quality contractors to get more work. I know I can speak for Hallen because it’s working for us.

This is where it really benefits all of us to roll up our sleeves and participate in DCA, not just sharing best practices, but also sharing regional trends that are likely to spread to others. Because just as contractors and utility companies get together in organizations like DCA, the Northeast Gas Association and the American Gas Association, regulators are meeting and sharing information, too.

The Northeast, for example, has taken a very proactive and aggressive approach toward adhering to new regulations that are coming at a level we’re not seeing yet in in some other parts of the country. Whether its pipeline safety management systems or the tracking and record-keeping of training, the industry is constantly trying to improve the way we perform our work.

Another reason is that it’s critical for us to communicate with each other and raise standards is because a bad contractor affects all of us. When there’s an incident because a contractor has not done what they’re supposed to do or has not been properly trained, it changes everything for everybody. We’re all lumped into that same bucket. That’s why it’s important being part of the DCA that we share our best practices together, our close calls together or anything like that, just so everybody understands. We all communicate that with all our committees.

UC: You’ve talked about changes for contractors, utilities and regulators, but how are the unions adapting?

Hickey: The unions in New York City have made incredible investments in training their people who want to come into the utility field. For years, it was all on the contractors, but the unions have set up schools now where they’re putting their people through very rigorous programs and actually weeding them out for us. In the distant past, if I needed a gas mechanic, I’d call up the union and they would just send me the next guy on their list. Now they do a lot of the work to prepare their members. They do all of the drug testing, the appropriate gas operator qualification training and testing, and they’re working with the utility companies directly to make sure that their programs are in compliance.

Now some of my peers would say, “Well, we pay for that when we pay the training portion of our benefit package.” I agree. But that’s always been there. When I was in the union back in the 80s and early 90s, they never put that money back into the actual training as they do today.

UC: Last year, Hallen Construction was acquired by Quanta Services. After decades as a family-owned and family-oriented company, how is this affecting your culture and direction?

Hickey: I’m thrilled to say that the Quanta people kept the entire executive team led by Shep Poole in place and are going to continue to let us run Hallen as we have successfully for so many years. I’m personally very excited about the possibilities for the future for Hallen and where this is going to take us and our future generations.

Comments