April 2019 Vol. 74 No. 4

Business News

Max Bgl

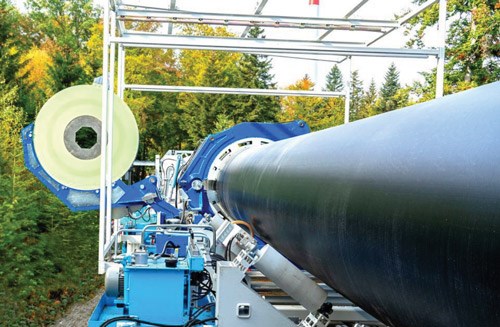

The Association of the Construction Industry, Environmental Technology and Mechanical Engineering (VDBUM) awarded Max Bögl Group’s PiPECrawler the first prize in the “Developments from Industry” category of the 2019 global innovation in underground pipelines made of polyethylene (PE) awards program.

“We are delighted to receive recognition from our colleagues,” said Peter Schmid from the Transport & Equipment sector of the Max Bögl Group. “We have developed a platform-based machine for laying thermoplastic pipes that is oriented towards industrial processes. This means that we can achieve three times the previous laying speed and can also work well in difficult terrain with grades and curves.”

The PiPECrawler has been in use since September 2018 on the Naturstromspeicher Gaildorf natural energy storage pilot project, the world’s first Water Battery that combines a wind farm with a pumped storage hydro-electric power plant. There, PiPECrawler lays the PE pressure pipe connecting the upper basins with the power station and the lower basin in the valley.

“Thanks to the self-propelled platform on which everything is pre-installed, there is almost no work to do in the pipe trench.,” commented Michael Hirth, project manager at Naturspeicher GmbH. “This makes our work both faster and safer. Additionally, the PiPECrawler was made especially narrow. This means we can plan with small working widths. Since the pipe uses an existing route, namely a service road in the forest, the tree population is deliberately spared.”

Proven in intensive collaboration

The concept of the PiPECrawler is a patented in-house development of Naturspeicher GmbH, a subsidiary of the Max Bögl corporate group. Headquartered in Sengenthal near Neumarkt, Bavaria, Max Bögl is one of the top-10 largest German companies in the construction industry. The pilot project, which has the world’s highest wind turbines, is being built in Gaildorf, Baden-Württemberg.

Comments