October 2015 Vol. 70 No. 10

Features

New productivity tools help HDD contractors work smarter, not harder.

The world’s aging infrastructure, expanding population and growing energy demands create an environment that will keep horizontal directional drilling contractors in high demand. At the same time, HDD contractors face new challenges, as project owners demand more information and detailed documentation — making current planning and recordkeeping processes inefficient and, sometimes, incomplete. As a result, HDD contractors can spend valuable hours backtracking to document actual bore details, and operations managers may lose time searching for information — leaving less time to pursue additional work.

The world’s aging infrastructure, expanding population and growing energy demands create an environment that will keep horizontal directional drilling contractors in high demand. At the same time, HDD contractors face new challenges, as project owners demand more information and detailed documentation — making current planning and recordkeeping processes inefficient and, sometimes, incomplete. As a result, HDD contractors can spend valuable hours backtracking to document actual bore details, and operations managers may lose time searching for information — leaving less time to pursue additional work.

As a leader in the HDD market, Vermeer listened to its customers, recognized the new demands they face and designed new tools to address their productivity challenges.

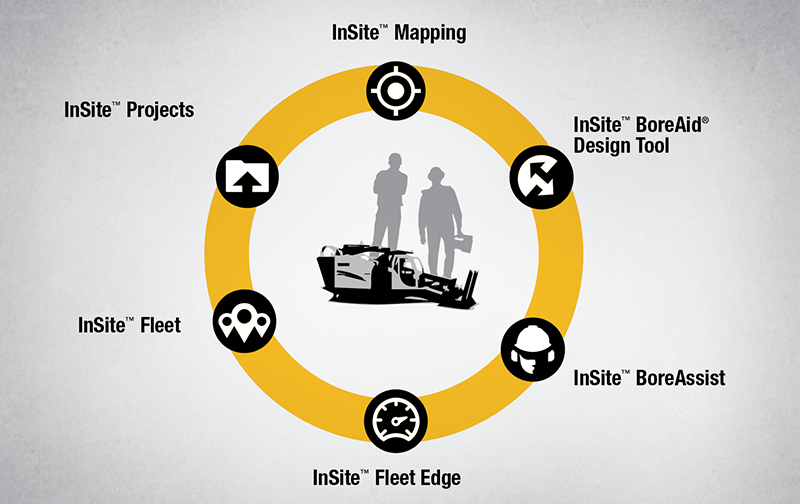

Introducing InSite™ Productivity Tools from Vermeer. They’re designed to help contractors better manage their business and make informed, real-time decisions every step of a project — planning, mapping, producing and invoicing — so contractors can be confident they have the right plan and the right equipment in the right place at

“InSite Productivity Tools eliminate the old manual, on-paper method and provide an electronic record of a project, which helps expedite invoicing,” says Jon Kuyers, senior global product manager for Underground at Vermeer. “The tools can be used individually or work together. And they can be accessed by multiple parties — making collaboration and real-time information sharing possible.”

Easier fleet management — With the expense of routing crews to the right machine and location and the time spent hunting down information — including maintenance documentation and machine location — fleet managers have their hands full. InSite™ Fleet is a remote monitoring software that gives operations and fleet managers machine information, such as fuel consumption, fault codes and engine idle time. InSite Fleet was previously introduced as InSite™ Asset Management.

Productivity tracking — Rising equipment costs and tight operating budgets make productivity tracking and cost control increasingly important. InSite™ Fleet Edge is an optional productivity enhancement that conveys actionable machine information — including productivity tracking, maintenance prioritization, fuel savings estimation and jobsite time management.

Efficient project planning and data storage — With stacks of paperwork, a hectic jobsite and unexpected plan changes, there’s the potential for crews to miss steps in the jobsite process. The InSite™ Projects planning tool can organize jobsite workflow and plan an installation via a computer, tablet or smartphone. Project data is stored digitally — shareable electronically with project owners, inspectors or other key stakeholders to help speed up approvals or job documentation. Once the job is complete, the user can export a project report.

Advanced bore planning and design — More and more, project owners demand a consistent, electronic bore record to help verify proper design, planning and installation. The InSite™ BoreAid® Design Tool guides the user through a bore planning process using soil information, product type and properties, physical obstacles and other key data entered by the user to provide a comprehensive understanding of feasibility and identify potential issues — then creates a detailed plan in line with industry standards. The user can generate reports for the anticipated bore plan and feed information into the bid documents or operational plans.

Accurate, sharable

mapping data — Ideal for complex jobsites, InSite™ Mapping is a GPS-enabled mapping application that can allow the marking of a proposed bore path and aids in documenting marked utilities, hazards and landmarks. The user can then enter data directly into InSite Projects to generate an intuitive, top-down view of jobsite information that’s shareable with the team.

On-rig bore planning — Adapting to unplanned issues on the jobsite can be difficult. The InSite™ BoreAssist on-rig application allows the operator to load, edit and review the bore plan on the DCI® DigiTrak® Aurora™ display, then follow the rod-by-rod plan and compare locate information to the plan. The operator can also design a simple bore in the field using templates that can be shared electronically. Drill data can be logged with the push of a button — reducing the need for operators to log information on paper.

From bid to bill, InSite Productivity Tools from Vermeer help underground contractors plan, map, produce, invoice and manage HDD projects — leading to less paper and real-time access to vital information they need to make decisions and be more productive. The full suite of InSite Productivity Tools will be available in early 2016 through the Vermeer global dealer network.

From bid to bill, InSite Productivity Tools from Vermeer help underground contractors plan, map, produce, invoice and manage HDD projects — leading to less paper and real-time access to vital information they need to make decisions and be more productive. The full suite of InSite Productivity Tools will be available in early 2016 through the Vermeer global dealer network.

The Capabilities Guide is a yearly feature in Underground Construction’s October issue. It is a special advertising section in which advertisers are given free matching space to highlight their company, services and products.

Vermeer, the Vermeer logo, Equipped to Do More, InSite and BoreAid are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. DCI, DigiTrak and Aurora are trademarks of Digital Control Incorporated.

© 2015 Vermeer Corporation. All Rights Reserved.

Comments