August 2013, Vol. 68 No. 8

New Products

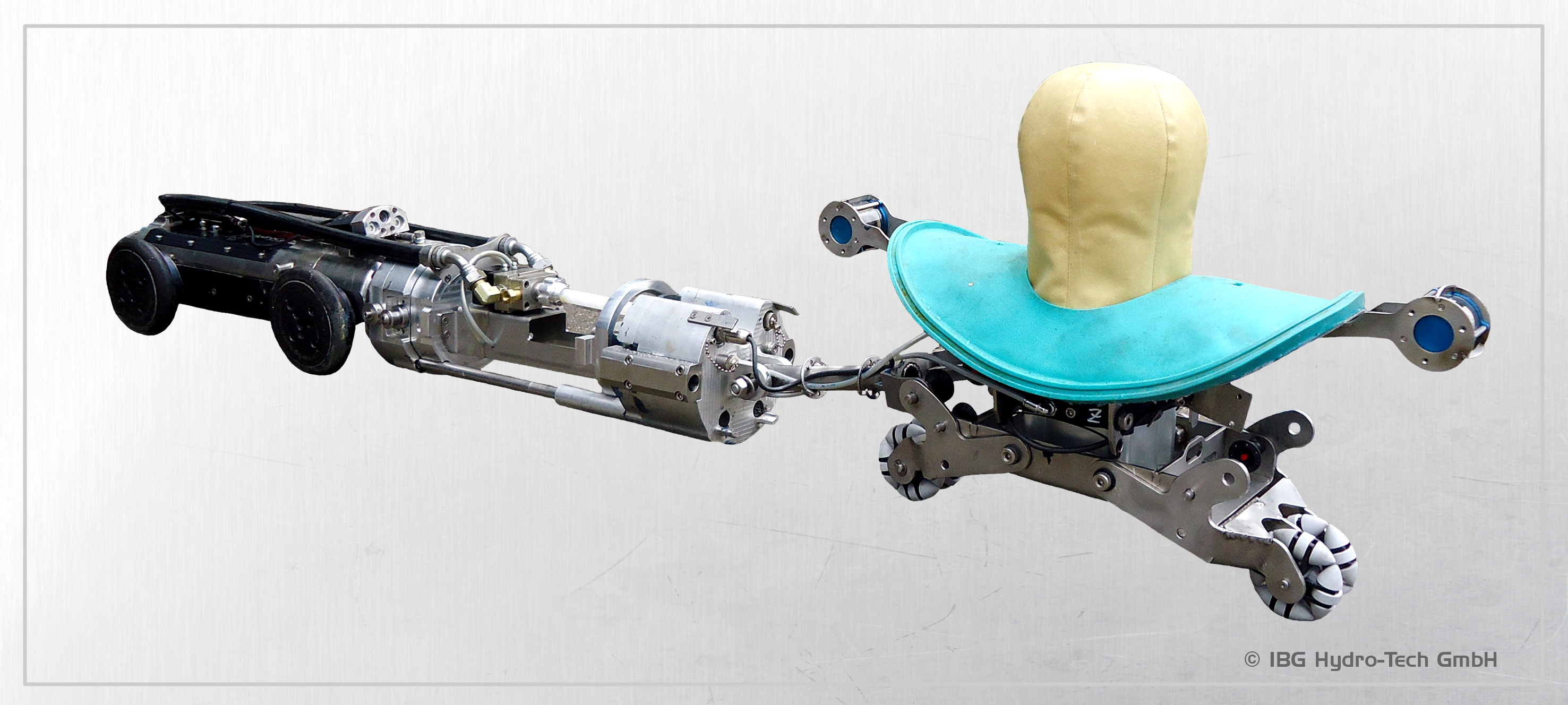

IBG 2K Hybrid-Grouting-System Tested

The IBG 2K Hybrid-Grouting-System designed by IBG Hydro-Tech rehabilitates lateral pipe joints or lateral connections with the main sewer after cured-in-place pipe lining has been completed.

Complete documentation makes every operation step traceable and ensures reliable work on the job-site. At the control unit, the user can see a schematic of the mixing equipment of the hybrid resin with pumps, storage basins, valves and different measured values. It consists of two 200 liter material tanks. An electronically controlled pump is used to fill and remove the grout components. A 100 meter hose is connected to the tank that supplies the resin to the operating system in the sewer. Just seconds before the resin is injected into the lateral, the two components are mixed to form the hybrid resin. To ensure a constant temperature of the components, the tanks and the hose drum are built into an air-conditioned box. With three mounted cameras, the user can control the process from different views and is able to react to various rehabilitation situations. One camera is located on the carriage, and two are located opposite each other on the shield. The sealing packer size is adjustable to the lateral diameter and is available in four sizes: ID 100, 125, 150, 200 mm (4, 5, 6 and 8 inch). These can be used for circular cross section laterals from ID 200 to 800 mm (8-32 inches).

Key features

• Applicable to circular cross-section pipes from ID 200 – 800 mm (8” – 32”) and egg-shaped pipes from ID DN 200/300 – 600/900 mm (8”/12” – 24”/35”)

• Highly economical due to the modular design and short processing time of the components

• Adaptable to IBG HydroCut carriage

• Carriage is easy to convert from cutting to spatula or grouting (cartridge system) operation

• Easy to use with cartridges or disposable bags as resin containers (cartridge system)

• Heated shields allow retraction after 45-60 minutes (grouting system, cartridge system)

• Use of all common epoxy resins and robot silicates is possible

• Available as a mobile unit or with equipment mounted in a vehicle

System advantages (subhead)

• Short-time frame procedure means increased daily output

• Documentation without interruption

• Process reliability and quality control

• Easy handling with the computer-controlled process cycle

• Hybrid resin with superb chemical and physical properties (adhesive tensile values on the liner surface up to 400 percent higher than previous types)

For More Information:

IBG Hydro-Tech: +49 (0) 6042 / 95 64 0, www.ibg-hydro-tech.de

Comments