Austin Energy's distribution system undergoes assessment for underground feasibility

(UI) — The Austin City Council approved Austin Energy’s third-party contract for evaluating the electrical utility’s more than 12,000 miles of electrical distribution lines, the company said on Feb. 16.

Twin independent studies by engineering firm Burns & McDonnell will begin in March 2024 to assess the underground feasibility and overhead resiliency of Austin Energy’s distribution system.

The contractor will evaluate the distribution system which consists of approximately 7,000 miles of underground and 5,000 miles of overhead lines. The goal is to identify potential improvements to ensure the continued safe and reliable delivery of power to Austin Energy’s electric customers with a focus on risk management and resiliency.

“Austin Energy is excited to embark on these studies with an eye toward continually improving electric service reliability and resiliency,” said Elaine Veselka, Vice President of Electric System Engineering and Technical Services. “We feel this is much more than a ‘one size fits all’ approach to improving resiliency and can help guide our ongoing efforts.”

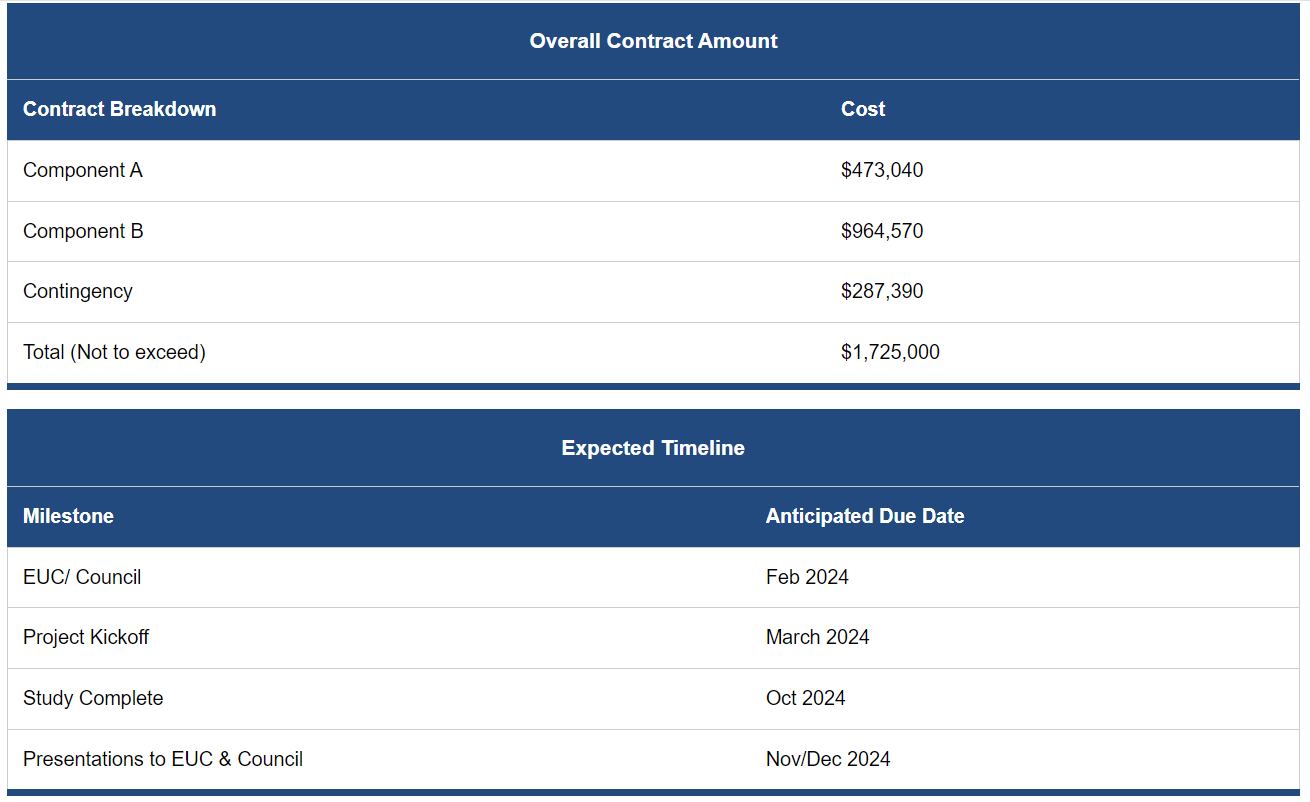

After Winter Storm Mara in February 2023, AE executives directed staff to budget money to conduct an undergrounding feasibility study. In March 2023, the Austin City Council adopted a resolution further directing the utility to study the feasibility of converting existing overhead distribution lines to underground lines (referred to below as Component A).

In April 2023, the Federal Energy Management Agency awarded Austin Energy a Building Resilient Infrastructure and Communities grant to study the resilience of Austin Energy’s overhead distribution system (referred to below as Component B).

These studies are separate, independent initiatives but require much of the same Austin Energy resources to complete. By combining the efforts, the utility will benefit from deliverable results that complement each other, as well as cost savings on internal resources.

For example, if Component A determines undergrounding is prohibitively expensive in one area of the system, Component B may offer an overhead alternative that is more cost effective; yet still increases reliability and resiliency.

Related News

From Archive

- Glenfarne Alaska LNG targets late-2026 construction start for 807-mile pipeline project

- U.S. water reuse boom to fuel $47 billion in infrastructure spending through 2035

- $2.3 billion approved to construct 236-mile Texas-to-Gulf gas pipeline

- Major water pipe break in Puerto Rico hits over 165,000 customers

- Potomac River Tunnel project enters construction phase beneath Washington, D.C.

- Pennsylvania American Water launches interactive map to identify, replace lead water service lines

- Trump's tariffs drive $33 million cost increase for Cincinnati sewer project

- Utah city launches historic $70 million tunnel project using box jacking under active rail line

- Tulsa residents warned after sewer lines damaged by boring work

- Fatal trench collapse halts sewer construction in Massachusetts; two workers hospitalized

Comments