May 2023 Vol. 78 No. 5

Features

Challenges become firsts in Chelsea River Crossing project

Untold Story of a Key ‘Big Dig’ Project and Fundamental Role of the Contractor

(UI) — What attracts many contractors to underground construction are the challenges – geological, mechanical and/or technological – they face. More than in other fields of construction, contractors have the leading role in deciding on the course of events that they, alone, can control. As a result of overcoming challenges, technological firsts can be established.

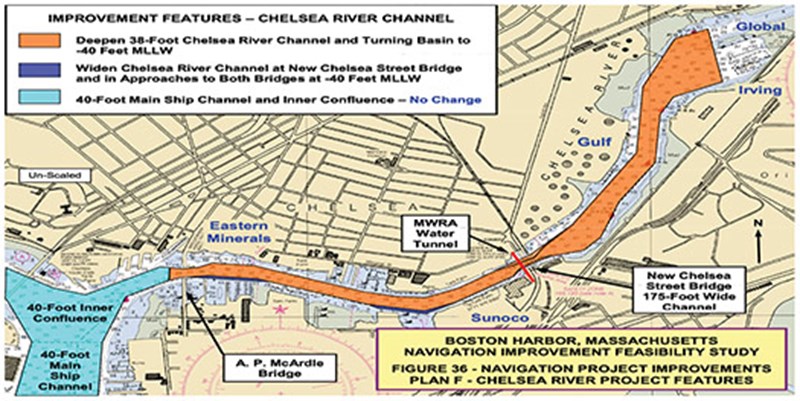

This was definitely the case with Massachusetts Water Resources Authority’s (MWRA) project to replace a pressurized water syphon under the Chelsea River channel at the North Point Fort area of East Boston.

It involved installation, by means of a 1,100-linear-foot (LF) microtunnel under the river, with a 72-inch diameter drive allowing insertion of a 48-inch diameter cast steel pressure water line.

Diaphragm walls were used for the construction of both launch and receiving shafts, with an invert 85 feet down from the ground surface. In view of occasional boulder obstacles in the till, a new Soltau RVS 800 machine, powered by three planetary motors, was selected to allow access to the face through the bulkhead to eventually break down the obstacle under compressed air.

A hyperbaric chamber was available onsite but was never used. A 72-inch diameter, one-inch-thick Permalok pipe was used as the jacked pipe, the largest diameter available at the time. Although an exit seal was present at the launch shaft, no re-entry seal was planned at the receiving shaft, given the uncertainty about accurately reaching the target.

The geological profile along the alignment was through glacial till with a coarse alluvium passage in the middle of the bore corresponding to the Chelsea River bed original thalweg. The ground cover between the bore and the river bed was approximately 35 feet.

Firsts achieved

In the course of this project, numerous firsts were performed that contributed substantially to the progress of microtunneling technology that is of great use in today’s ever-intensifying conquest of underground space:

- Tri-motor U.S. cutting head drive micro-tunneller slurry shield

- Over 1,000 LF of 72-Permalok jacked pipe drive

- Dry receiving shaft entry with 80 feet of head and dynamic annulus grouting

- Annulus backfilling by gravity flooding with slow-setting slurry-grout

The project was completed during the summer of 2000.

Once underway, jacking forces became a concern even before reaching the alluvium. Machine interruptions were caused by breakdowns, due mainly to the abundance of boulders, and the high alluvium permeability required lubrication improvements that were implemented successfully.

Despite mechanical problems with the equipment, the question of how to arrive at the receiving shaft in the dry, with possibly an 80-foot water head on the annulus, became a preoccupation for all involved. Receiving the machine in the wet was not an option due to subsequent machine scheduling on another project.

Implementing an annulus controlled dynamic backfilling, with specially formulated self-hardening slurry, provided the solution for an exit in the dry into the receiving shaft.

Access shafts construction

The general contractor, utility contractor Modern Continental, undertook specialty disciplines, such as deep foundations, inclusive of diaphragm walls, microtunneling (assisted by Westcon), on top of regular heavy construction activities.

Challenges included installing a circular slurry wall, a classic method for deep shafts sinking in soils, using conventional clamshells and chisels under bentonite slurry.

On the North Point side, old deep seashore obstructions, as well as boulders on both sides, created trenching difficulties that were overcome but resulted in substantial concrete over-pours and required joint leakage mitigation techniques. Very hard till soil at subgrade allowed an excavation in the dry without requiring a tremie seal, despite the hydrostatic head.

Finally, the shafts performed well, as intended.

The Soltau RVS 800 was a new slurry shield type of machine. Water is used to convey the excavation spoil to the surface, where a solids separation plant removes the cuttings and recirculates the water. Depending upon the soil, bentonite or polymers are added to the water to reduce outbound slurry losses and improve face stability. Permalok joined jacking pipes represented a technological advancement and 72-inch was the largest diameter available.

Further, Modern Continental had gained substantial experience with microtunneling around Boston, albeit on shorter and shallower drives.

As is typical with all new machines, breakdowns were inevitable.

Eventually, boring issues led to the replacement of some motors and gearing, immobilizing the machine at crucial times. The till contained many more boulders than anticipated by the DBR, causing slow progress and hardship for the machine.

During interruptions, lubrication with bentonite slurry was attempted. However, with 80 feet of external head pressure, high lubrication counter-pressures caused some leakage at the entrance seal, ultimately allowing brackish water to appear. A doubling of the entry seal eliminated this problem and allowed reconditioning of the annulus.

Lubrication

High lubricant pressure causes thick mud cakes to form, by filtration at the interface of the bore with the ground, reducing the annular space and potentially increasing future jacking forces. Delays and brackish groundwater would have a negative impact on bentonite filtration performance and could cause even thicker mud cakes than in a fresh water environment.

For the 20-foot long Permalok pipe sections, lubrication ports were initially provided every other pipe, or at a 40-foot gap. This was an optimistic approach to lubrication that proved workable, until mechanical breakdowns interrupted the drive. Further on, getting into the pervious gravelly alluvium of the Chelsea River’s thalweg, the loss of lubrication efficiency increased jacking forces to a level that compromised the ultimate goal.

An intermediate jacking station was built and installed in record time, thus making drive completion plausible. High alluvium permeability allowed the bentonite slurry to escape through the gravel, possibly breaching the river bottom and preventing the maintenance of sufficient counter pressure to maintain the annulus’ integrity. Jacking pressures increased significantly, in view of being only at mid-point of the drive, using more than two-thirds of the available jacking force.

When a crab surprisingly appeared on the shaker screen of the solids separation plant, it was considered a prank or a sign of a breakthrough to the river – which could be possible, under the circumstances. The mystery was never solved, but induced serious efforts in controlling the annulus, including increasing the number of lubrication ports to each pipe section.

Another approach was formulating a much thicker lubricating slurry, with very low filtration, using more bentonite, polymers and other gelling additives. This was implemented all along the 240-LF alluvium on the alignment, before reverting to a straight bentonite/polymer lubrication at each pipe and once regaining control of the annulus past the river thalweg.

In addition, it was decided that the lubrication around the machine should be achieved independently of the jacked pipes. A direct line to the machine shield’s ports was installed and dubbed the “Bentonite Express.”

With the addition of the intermediate jacking station, boring progressed slowly, but regularly, and removed any doubt about the outcome. Friction forces of the section forward of the intermediate jacking station were maintained at a normal level, thanks in part to Bentonite Express saturating the annulus around the trailing pipe.

The section behind the intermediate jacking station flirted with maximum jacking frame capability available from the launch shaft but did crawl forward.

Exit

It is not known whether the accuracy of the guidance system, or the contractor’s lack of confidence with such a long drive for the times, removed the possibility of reaching the receiving shaft on-target through a receiving seal.

Typically, in such a situation, the response is to exit in a flooded shaft and retrieve the machine with the help of divers. This was not an option, because the machine was committed to another project and the current job was well behind schedule, leaving no time to recondition the flooded machine.

The problem was how to exit in the dry with an annulus under 80 feet of head, with a potential communication in the Chelsea River. An imaginative solution had to be devised without delaying the progress of the machine.

Since the bore was back in the glacial till, the ground was considered as essentially impervious, albeit erodible soil. The challenge was then to impede any groundwater flow forward from the Chelsea River alluvium bed through the annulus into the receiving shaft. With concern for not increasing the jacking forces in any significant way, limited options were available to control the annulus.

The final plan was to create an active annulus sealing zone 40 feet long and about 60 feet away from the receiving shaft. This involved filling the annulus with a slow-setting, self-hardening slurry-grout that would pack the annulus with a mud cake capable of resisting the hydrostatic head, while remaining plastic enough not to noticeably impact the jacking force, until the machine could eventually break through.

Injection pressures were maintained at all times, even during jacking pipe addition breaks. Injection ports were created for the train of pipes that would travel through the treatment zone, and connections were made, accordingly, to keep the process dynamic until breakout and machine extraction.

The fact that the injected formulation was, nevertheless, cementitious required close coordination between all trades. Time was of the essence, with activities taking place around the clock.

Based on rates of progress, the active sealing zone would start setting after the fourth day. Breakthrough did occur after three days. Modern Continental was willing to risk that the last 60 feet of the bore forward would be glacial till, consistently, with no saturated seam leaving the bore unprotected.

The gamble paid off with the exit through the diaphragm wall occurring in a perfectly dry condition. The active zone was maintained until the trailing tube was extracted and the pipe penetrated through the diaphragm wall. Conventional sealing and waterproofing were performed from inside the shaft.

Installation of the 1,100-LF 48-inch cast steel bell and spigot pressure pipe riding on radiant spacers sliding on plastic pad was a new challenge in itself. Given the fragility of three rings per 20-foot pipe section, Modern had to pull out on a few occasions to replace damaged spacers.

Annular space backfilling

Following successful pressure testing of the service pipe, the final challenge was to grout the annulus between the 72- and 48-inch pipes. Installing grout lines concurrently with the service pipe would have been difficult and quality control virtually impossible, after insertion of the pipe.

Modern proposed and MWRA approved a novel approach: grouting the entire length of the 1,100-LF drive by bulkheading both ends of the annulus at the shafts. This provided an entry port at the invert on the launch shaft and a vent port at the spring line at the receiving shaft, both connected to a riser to the surface.

Slow-setting, proprietary, non-shrink, self-hardening slurry was mixed on the surface and dropped to the bottom of the shaft through a three-inch riser connected to the entry port. By flooding the annulus from one end to the other, the annulus backfilling was completed with no possibility of trapping air.

Once the slurry-grout emerged through the exit riser at the surface, with the same density as when going in, backfilling was terminated and kept under the vertical column pressure, until completely set, in about one week. Although it could have taken place over a single long shift, given the slow setting nature of the formulation, the backfill was completed in two short shifts. The simplicity of the process inherently carries assurance of a 100-percent homogenous annulus backfill.

ABOUT THE AUTHOR: Gilbert Tallard is a civil engineer whose career has been linked to many aspects of underground construction and environmental remediation. His specialty is drilling and support fluids, grouts and self-hardening slurries. At the time of this project,

he provided Modern Continental with lubrication and self-hardening slurries advice and formulations. Also contributing was material referenced from a paper on geological and mechanical aspects of the project: Challenges and Successes in Micro-Tunneling in the Chelsea River Crossing by Peter J. Tarkoy, Ph.D.

Comments