July 2023 Vol. 78 No. 7

Features

Caverns of Calloway – Dirt pipes are expensive

by Tom Davies, P.E. and Gary Oradat, P.E. of Trinity River Authority of Texas, and Nicole Conner, P.E. of Kennedy Jenks

After a heavy rainfall in June 2022, the Trinity River Authority (TRA) was notified of a sanitary sewer overflow (SSO) on a sewer line within the Walker Calloway System, a 4.7-mile wastewater collection system built, owned and operated by TRA. The line delivers wastewater from North Richland Hills and Hurst to a discharge point in the Fort Worth wastewater system for further transportation and treatment.

The TRA is a state-level agency tasked by the state of Texas with managing the quality of water in the Trinity River watershed throughout the state, from its most upstream reaches near the Oklahoma border to where the river discharges into the Gulf of Mexico near Baytown, Texas. The TRA Northern Region collects and treats 235 MGD of wastewater for 1.5 million people in the DFW region in north Texas.

The Walker Calloway System is unique in the TRA system in that the interceptor is maintained but flows are not treated. TRA agreed to take over the operation and maintenance of the interceptor as a service approximately 20 years ago to minimize service disruptions and maximize maintenance efforts. Hurst and North Richland Hills approve and give funding for capital upgrades, but TRA implements and oversees them.

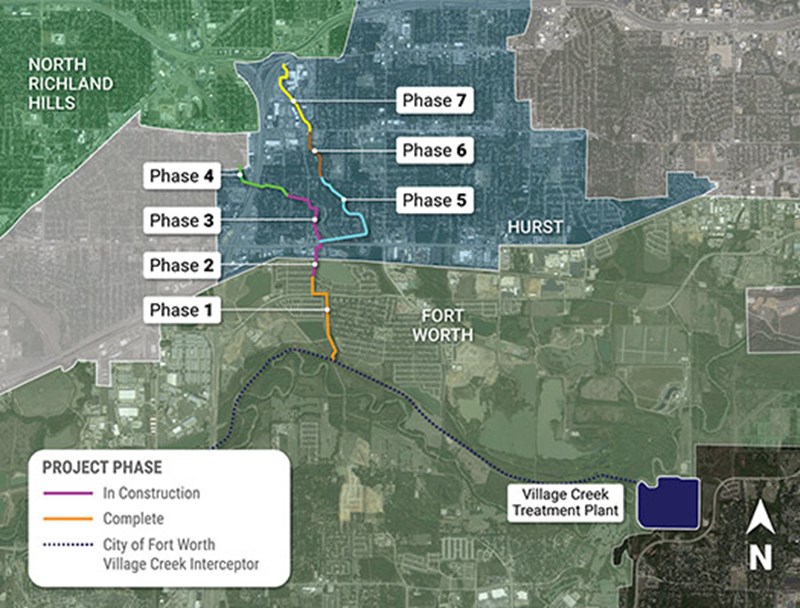

TRA commenced a capacity and condition assessment in 2011, and a program to rehabilitate or replace the interceptor’s seven primary segments (FIGURE 1), beginning at the downstream end of the interceptor, was initiated in 2016. Each phase of the program is comprised of several thousand feet of wastewater pipeline: Phase 1 construction was completed in February 2020, construction of Phases 2 and 3 is imminent, and Phase 4’s final design is underway (preliminary design was completed in May 2022). Despite the advancement of the rehabilitation work, the deterioration of the original pipeline continued, eventually contributing to a large SSO in the interceptor’s Calloway Branch.

Storm damage

This segment of the original Walker-Calloway System was constructed of 27-inch unlined reinforced concrete pipe (RCP) in 1970. Late afternoon on Friday, June 4, 2022, the Calloway Branch of the Walker-Calloway drainage channel system was overwhelmed by a significant rain storm that produced nearly four inches of rain in less than two hours. Flows accumulated swiftly in the Calloway Branch drainage channel, overpowering numerous bridges that span over it, and also found their way into the Walker-Calloway interceptor system as infiltration and inflow.

Almost immediately following the heavy rain event, a resident noticed an overflow at a sewer manhole and contacted the city of Hurst. The city noted upon arrival that the overflow was on the TRA managed portion of the system.

With a history of blockages and collapses, TRA was set to award a contract for final design to replace and rehabilitate this segment of the pipeline when the SSO occurred. TRA staff mobilized immediately and worked expediently and progressively to determine if this was another blockage or more significant pipe break.

This segment of the system is located in a channel with 25-foot tall sidewalls which hindered equipment access. In order to isolate the line for investigation, the contractor not only set up a traditional bypass for the line, but also sent equipment into the drainage channel to build earthen berms to contain the wastewater overflow within the work area. Two trailer mounted pumps were used to pump the water contained between the berms located at manhole 210WC and downstream at 180 WC out of the drainage channel and into manhole 180WC to prevent downstream contamination, as depicted in FIGURE 2.

Preliminary examination confirmed the blockage was located somewhere between manhole locations 200WC and 190WC. At manhole180WC, cleaning trucks were stationed over the downstream manhole. Unfortunately, the torrential rains saturated the earth around manhole 180WC, limiting truck access and causing setup to take hours rather than minutes. A separate cleaning vehicle was stationed over manhole 190WC and attempted to clear debris from the pipe between 190WC and 200WC. Several passes of jetting were attempted to dislodge the obstruction were unsuccessful, but they verified the presence of a large blockage five to 10 feet upstream of manhole 190WC. The apparent challenge was to clear a blockage located under the reinforced concrete apron of the drainage channel, approximately 25-feet deep and adjacent to a residential home. It was discovered that continued corrosion of the 27-inch RCP had left no remaining pipe across the channel floor and, due to the blockage, it was unclear how much pipe wall remained under the channel sidewall.

HDD cleanout

A horizontal directional drilling rig was brought in to clean out the debris from inside the collapsed pipeline in order to minimize deep excavation near the residence. The purpose was to place a steel encasement pipe beneath the drainage channel wall up to manhole 190WC reestablishing a clear passage up to the exterior of the manhole. After the encasement pipe was installed, a new carrier pipe would be inserted within to transport the wastewater.

The steel encasement pipe was successfully put into position after only a few hours of work. The blockage under the wall was cleared and the encasement pipe was installed. Unfortunately, another challenge was soon encountered.

Manhole 190WC is a point of inflection that redirects the pipeline to parallel the drainage channel and is also a drop connection point-of-entry to the interceptor. The connections were not installed in vertical alignment but were offset where they connected to 190WC. This required the TRA team to excavate the connection to reconnect the manhole. During the connection excavation, a significant (20-foot) void close to manhole 190WC (FIGURE 3) was discovered, extending under the drainage channel wall and private driveway, jeopardizing the structural integrity of both structures.

The prevailing hypothesis is the original pipe collapsed behind the drainage channel wall, forcing the fill above the failed pipe and below the driveway to wash into the interceptor, leaving a void. Thankfully, the void was discovered before it collapsed causing damage to the driveway and automobiles above. To fully repair the interceptor and properly fill and compact the void, the channel wall and driveway were sawcut and removed, and shoring was installed (FIGURE 4). The original manhole 190WC was removed and replaced with a polymer concrete manhole that is resistant to corrosion and erosion from grit and abrasives.

More challenges

Additional challenges were encountered when reconnecting the downstream line to the new 190WC manhole. The pipe was disintegrating when a rubber boot connection was attempted and a significant amount of large debris (FIGURE 5) was located in the line. Images showed hanging joint gaskets, infiltration holes, and extensive exposed reinforcement. Any level of vigorous cleaning to remove mud and debris would present serious risk to the existing pipe. The contractor utilized a custom bucket (FIGURE 6) made from a section of steel pipe with a rebar “filter” welded on to catch large rocks while allowing water and sediment to pass through. Cables were attached to the front and back of the basket to drag it back and forth and to prevent the basket from getting stuck. Once the large debris was removed, the pipe between manholes 190WC and 180WC was replaced via pipe bursting.

Though HDPE DIPS DR-21 was sufficient for the depth of cover between 190WC and 180WC the summer of 2022 was fraught with material shortages. In the entire United States, there was not a 208-foot quantity of external diameter of 30-inch HDPE DIPS DR-21 available. Though it resulted in a smaller internal diameter, the team obtained HDPE DIPS DR-17.5 in quantities sufficient to complete the installation. Despite the smaller internal diameter associated with the stiffer DR-17.5, it was determined to be sufficient to carry the expected flows in this segment of the system. The materials and bursting cone came from New Mexico and Chicago, respectively, and were on site in less than five days. Once set-up was complete, the actual bursting was finished in little more than an hour.

Flow was restored on July 1, 2022, and final site restoration completed the concrete channel wall and residential driveway. In addition, a new fence and fresh landscaping were installed at the impacted residential property.

The Walker-Calloway emergency repair started out as an SSO event that evolved into a bigger infrastructure challenge as the investigation unfolded. Early frustrations eventually yielded positive results with some valuable takeaways. Maintaining good relationships with suppliers, contractors and engineers is valuable in an emergency and you must remain flexible with approach and materials. Expect the unexpected and just keep going. While the depths of the existing pipe and the close proximity of house to the work area presented significant challenges, proper planning by the engineering team, professional execution by the contractor and good quality control by the inspectors led to a successful repair of a deteriorated section of the Walker-Calloway Interceptor System and the legendary Caverns of Calloway.

FOR MORE INFORMATION

Flow-Line Construction, (214) 390-2848, flow-lineconstruction.com

Circle C Construction (pipe bursting), (817) 383-2119

Comments