January 2022 Vol. 77 No. 1

Rehab Technology

Sewer Line Root Intrusion: Prevention and Removal

By Sean Comerford, Oatey Co.

Root intrusion is one of the most damaging problems to discover in a sewer system. Roots thrive in sewer lines because they are well-ventilated and provide an excellent water source. While that’s great for plants and trees, it can have a devastating impact on a sewer system.

Root intrusion can block sewer lines and affect the sewer system’s hydraulic capacity, i.e., ability to maintain or pass a given flow rate. A clogged sewer pipe will lead to slow drains, unpleasant odors caused by standing water within the drain line and damaging overflows.

In old clay sewer lines, drain sections were connected by inserting a non-bell (hub) end of the pipe into the hub of the next section and filling the gap with concrete. With time, the concrete deteriorates, and roots grow through the openings and expand, damaging the piping. Roots can also grow through partially collapsed pipe or even rotted-out cast iron.

Preventative measures

Professionals can help prevent sewer root intrusion at the installation step by ensuring proper backfilling. The area around the pipe is compacted to help prevent the pipe from sagging or forming bellies in the line. Sagging can cause stress, leading to breaks, allowing roots to enter.

The International Plumbing Code states: “Backfill shall be free from discarded construction material and debris. Loose earth free from rocks, broken concrete and frozen chunks shall be placed in the trench in 6-inch (152 mm) layers and tamped in place until the crown of the pipe is covered by 12 inches (305 mm) of tamped earth. The Backfill under and beside the pipe shall be compacted for pipe support. Backfill shall be brought up evenly on both sides of the pipe so that the pipe remains aligned. In instances where the manufacturer’s instructions for materials are more restrictive than those prescribed by the code, the material shall be installed in accordance with the more restrictive requirement.” ~ 306.3 Backfilling

While proper backfilling is a reliable way to aid in preventing root intrusion, deterioration of concrete or rotted-out cast iron is inevitable over time, allowing roots to grow through the openings.

If left untreated, root intrusion can eventually lead to a complete collapse of the sewer system. The roots on the outside of the pipe will encapsulate the pipe, creating pressure that will cause the sanitary system to collapse and shut down.

At that point, the last resort would be to dig up the sewer line, costing the homeowner thousands of dollars depending on location. Pipelining offers an alternative solution to avoid digging up the damaged sewer line. A cured-in-place pipe (CIPP) epoxy liner is applied to the inside of the pipe, sealing any opening or gaps to stop leaks and prevent future root intrusion. Chemical root control is also a viable option.

Manufacturers offer various tools for cutting and cleaning out roots. However, it’s important to follow certain steps to avoid damaging the sewer line. Below, we outline some common root-removal methods and best practices for professionals.

Mechanical removal

Once severe root activity is identified within the sewer line, the roots must be removed with a mechanical, root-removal tool. Cutters, nozzles, cable machines and jetters are often needed for severe blockages.

Snaking the line with a root cutter is one of the most common ways to remove roots. But be sure the heads and bits used on the ends are specifically designed for cutting out roots. Some heads can expand to adjust to the exact inside diameter of the pipe, completely cutting the roots down to the inside face of the pipe.

This function is particularly helpful. Many cutting tools will leave two inches of roots at the top because they do not fill the entire inside diameter of the pipe.

Keep the following in mind when snaking the line with root cutters:

- Proper cable size: If you don’t use the right cable size, you could either damage the tool or cause an injury. Say, for instance, you use a smaller snake, it will get caught in the roots and you’re left with a 20-foot cable stuck in the line.

An improperly sized cable could get wound-up or whip back, potentially leading to an injury. - Proper head size: As noted above, if you use the wrong head size, you won’t get a full cleaning of the inside diameter of the pipe. Sizing is based on the pipe diameter. Most sewer lines will be three to four inches, but the main sewer line could be larger in commercial applications. A standard rule of thumb is to use a cable at least ¾ inch to an inch in diameter.

- Maintaining mechanical equipment: Maintenance is key. If the root cutting head is dull or damaged, it won’t be as effective. This also applies to snake cables. If a cable is kinked or bent, it can cause it to bind up and result in injuries as well as ineffectiveness because it has a weakened point. It could even break off and get stuck in the sewer.

Sewer jetting is another common practice for root removal. Jetters consist of a high-pressure water pump, water tank, hose reel and ½ inch to 1-inch sewer cleaning hose. A sewer jetter is a great tool to remove piled-up root debris that remained in the pipe after using a root cutter.

Chemical treatment

Chemicals are great preventive maintenance tools after mechanically removing roots from the sewer line. They open, clear and prevent root-clogged drains and sewer lines. There are several options available on the market today. Some include foaming chemicals composed of metam-sodium. Foaming equipment may be required to create the foam that enters the pipe.

Another effective chemical treatment is copper sulfate crystals. This inorganic compound that combines sulfur with copper can kill bacteria, algae, roots, plants, snails and fungi. These chemicals are formulated to eliminate and prevent root growth in sewer-type lines.

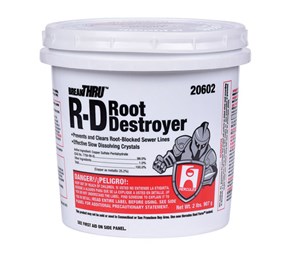

For example, Hercules R-D Root Destroyer is a special flake-like formula that prevents and stops root growth in external drain lines. Because this formula interacts with water, the drain line will need to be mechanically opened (snaked) to allow water flow if it is completely blocked.

Once the line is open, a service tech can apply Root Destroyer at or near the root clog’s location. Adding a treatment before bedtime will allow the Root Destroyer to work overnight without being flushed out too soon.

R-D Root Destroyer uses a non-acid, non-caustic herbicide formula that is safe for pipes leading to septic tanks, cesspools and drywells. Large “root grade” crystals are blended with an active wetting agent enabling R-D crystals to adhere to the root mass longer, dissolve slower and effectively kill and eliminate root blockages.

In most cases, several days should be allowed for the infiltrating roots to die, decay and wash away after absorbing dissolved R-D. Patience will be rewarded by the results of this proven method of root control.

Best practices

- Read all cautions and directions carefully before using a product.

- Have proper PPE available.

- Avoid contact with your skin, eyes, or clothing.

- Store the chemical in its original container and keep it in a locked storage area. Do not reuse the plastic bag or empty container. Rinse plastic bags thoroughly before discarding in the trash.

- Be sure the chemical you are using is allowed in your state or county. For example, Root Destroyer is an herbicide; therefore, it must be registered with each state’s EPA.

Some states do not allow copper sulfate to be used as an herbicide.

It’s important to understand that while chemical treatments will kill roots and prevent them from growing if used consistently, they won’t immediately solve the problem. First, it is necessary to mechanically clear the blocking after root intrusion is identified to ensure that chemicals can effectively flow through the sewer line and adhere to the root mass.

SEAN COMERFORD is a technical customer service specialist at Oatey Co. He is third-generation tradesman with nearly 20 years of plumbing experience, including serving as the lead plumber for commercial/residential new construction, service and fire protection jobs. He holds a State of

Ohio Fire Protection License for Sprinkler and Standpipe.

Comments