April 2022 Vol. 77 No. 4

Equipment Spotlight

Spotlight—Linings

Applied Felts

(276) 656-1904; appliedfelts.com

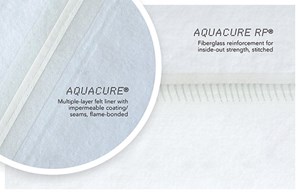

Using only the highest quality raw materials available, Applied Felts’ decades proven, PU-coated, all-felt AquaCure® liners, with stitched or flame-bonded seams, are built to meet your exacting standards. Our extra-durable, sewn-seamed, PP-coated version can withstand tougher on-site conditions and steam-cure processing, while providing greater flexibility in the field.

These liners are quality manufactured to conform to ASTM-1216, accommodating pipe diameters 6 to 120 inches, wall thicknesses 3-42 millimeters, and 45-degree bends – all in accordance with ISO 9001:2020.

Danby

(281) 598-1126; danbyrehab.com; danbypvclining.com

Danby PVC lining is used in rehab, new construction and precast to protect concrete from H2S gases and other corrosive elements.

The rehab process is 100-percent trenchless, using existing access in various shapes and sizes, and designed for 50 to 100 years of extended life. The smooth PVC surface improves hydraulic performance with minimum loss of diameter.

When incorporated during manufacturing of precast pipes and manhole risers, and during construction of cast-in-place structures, Danby PVC liner protects concrete from day-one.

The PVC liner is American made and known globally as a quality, rigid PVC liner for over 30 years.

FerraTex Solutions

(844) 433-7728, ferratex.com

Ferratex Solutions’ pre-impregnated liners, including glass-reinforced, gravity sewer AquaCure RP, and pressure application PS and PW versions, from our regional wet-out facilities, make your job easier. Our newest wet-out plant, adjacent to Applied Felts® in Virginia, is one of five locations across the country, offering logistical advantages and unmatched customer service throughout the U.S., Canada and parts of Mexico.

Upon completion of resin impregnation, our resin-saturated liners are loaded into our climate-controlled, refrigerated trailers for delivery and tracked through GPS.

Benefit from fully integrated QA/QC throughout the entire process – from polymer pellets and various fibers, to the refrigeration truck.

Flow-Liner Systems, Ltd.

(800) 348-0020, flow-liner.com

Flow-Liner’s CIP-Conduit® rehabilitates and extends the life expectancy of existing utility conduits, including fiber optic, telephone, and computer – without excavation and demolition. CIP-Conduit® is a trenchless lining product that reduces costly electrical and telecommunication grid downtime, along with being a green technology that reduces GHG emissions by over 80 percent.

Do yourself and the environment a favor, skip the old traditional methods of dig-and-replace and go trenchless.

HammerHead Trenchless

(800) 331-6653, hhtrenchless.com

HammerHead’s WT212-3D wet-out table features a unique, three-drive roller system and no-shim gap control that deliver highly accurate and uniform resin saturation for quality CIPP installations.

The latest curing methods require extreme consistency in resin depth and saturation. WT212-3D’s design powers rollers to reduce liner wrinkling common in hand-cranked models. The smooth, automated operation delivers uniform wet-outs time after time and a quick-locking gap mechanism allows users to calibrate gap height down to a quarter of a millimeter.

Inland Pipe Rehabilitation (IPR)

(678) 374-8194, teamipr.com

IPR’s proprietary process combines the most-advanced application equipment with a high-strength, low-porosity geopolymer. EcoCast is a completely trenchless lining system for large-diameter applications.

The process recovers and protects the pipe surface by filling in voids, cracks, and other defects with geopolymer material at structural thicknesses. EcoCast is a more cost-effective rehabilitation solution that extends the design life of your deteriorated piping infrastructure.

InnerCure

(844) 546-3772, innercuretechnologies.com

InnerCure Technologies Inc. has introduced a new technology to stop leaks at sewer mainline/lateral connections.

The InnerCure system consists of a fiberglass or felt lining material, a patented ring that provides a guide to position the lateral connection behind the mainline, rather than in it, and installation equipment.

The system can be applied either before or after a sewer mainline is relined. The InnerCure system can address the lateral connection only, or it can make the mainline connection and reline the lateral. after CIPP lining of the lateral is complete, InnerCure can be used to connect the lateral to the mainline sewer for immediate or future rehabilitation of the mainline without the need for excavation. The system provides a permanent structural seal at the connection and a chemically-bonded, seamless connection with a sealed annulus between the host pipe and the mainline liner.

IPEX USA

(800) 463-9572, ipexna.com

NovaForm™ is a styrene-free, expand-in-place, structural liner used for sewer and culvert rehabilitation.

Available in 6- to 30-inch diameters, the PVC liner allows municipalities to repair failing infrastructure while respecting the environment. Other benefits, versus open-cut replacement, include time savings, less disruption to local businesses and traffic, and flow capacity similar to new PVC pipe.

An engineered thermoplastic, with the only job-site discharge being water from condensation of steam, there’s no more capturing and treating contaminated curing liquid. NovaForm is manufactured in strict accordance with the ASTM F1504 standard and is third-party certified by CSA and BNQ.

LMK Technologies

(815) 640-9302, info@lmktechnologies.com, waterlinerenewal.com

LMK Technologies is the only provider of the ASTM (American Society for Testing and Materials) F2561-20 compliant T-Liner. This one-piece, homogenous, main-to-lateral CIPP connection liner renews 18 inches and 360 degrees of the mainline, extending up the lateral pipe as one continuous lining.

The T-Liner is offered with ASTM F3240-19-compliant Insignia compression gasket-sealing technology, which provides a verifiable non-leaking system.

MaxLiner

(877) 426-5948, maxlinerusa.com

The new Max VertiPox®, CIPP resin – 100-percent solids, styrene-free, two-part epoxy system – is uniquely formulated for vertical pipes and other in-building applications.

Its thicker viscosity prevents gravity-related resin run during installation and curing. Chemical resistant and odor-free, it adheres to existing pipe materials, even under very humid and wet conditions.

MaxLiner’s LED-based UV curing system, MaxLight, optimizes CIPP operations by dramatically increasing work efficiency. Curing doesn’t begin until resin is exposed to the finely calibrated UV light, so pre-impregnated liner assembly can happen at the shop or onsite, eliminating pot life concerns and enabling several installations in a single day.

Miller Pipeline

(317) 293-0278, millerpipeline.com

Miller Pipeline offers EX Method, a trenchless installation of EX Pipe causing no disruption to the natural environment or to urban residential areas.

EX Pipe is high-strength, un-plasticized and PVC manufactured under strict quality procedures using odorless, environmentally safe materials. The pipe is expanded-in-place, not cured-in-place, so factory-controlled, ASTM F-1504 uniform quality is assured for every installation.

National Liner

(800) 547-1235, nationalliner.com

National Liner, through its network of experienced North American installers, provides cured-in-place pipe (CIPP) products and services to municipal and industrial customers to rehabilitate deteriorated pipe.

Established in 1994, the company has installed more than 35 million liner feet of pipe, ranging in size from 6- through 96-inch diameter. Engineered with a 50-year design life, National Liner products and services economically rehabilitate damaged pipe.

NuFlow Technologies

(800) 834-9597, nuflow.com

NuCure Cold Cure UV is designed for 2- to 6-inch pipe and features dual power supplies and a proprietary Double Helix light train to ensure complete liner irradiance.

Our signature Precision Push/Pull-in-Place installation perfectly positions liners, and UV curing in as little as 10 minutes significantly reduces labor costs and provides outstanding ROI for installers.

The NuCure resin/light wave-length calibration developed by NuFlow experts creates a more controlled exothermic reaction, resulting in a true “cold cure” that does not require active cooling, provides a very dense cure, and ensures consistent quality in the end product.

Perma-Liner Industries

(866) 336-2568, info@perma-liner.com, waterlinerenewal.com

Perma-Lateral System, North America’s best-selling, small-diameter (2-8 inches) pipeline rehabilitation, requires only one access point, as the system can be installed through clean-outs or open-end pipes. The liner can be ambient-cured in 3 hours or steam-cured in as little as 20 minutes.

LightRay3 performs pull-in-place or spot repair operations by only changing the proprietary double-strand cold LED repair packer. The non-VOC resin is pre-impregnated into the high-performance fiberglass liner and shipped ready-to-install.

Once the site is prepped, casting time can be under 10 minutes, eliminating the risk of premature or prolonged curing times due to temperature variations.

Pipeline Renewal Technologies

(866) 936.8476, pipelinert.com

SpeedyLight+ is the LED-based solution for CIPP that cures liners with half the power. With cure speeds up to five times faster than traditional technologies, SpeedyLight+ lives up to its name.

Compatible with felt and invertible glass fiber, SpeedyLight+ can cure transitions, verticals and even 90-degree bends in lines as small as 4 inches. The integrated camera lets operators monitor the curing process in real time, allowing for ultimate precision.

Free of styrene and amines (and the associated odor), light-based cure technologies are less disruptive than their ambient counterparts.

Primus Line

(704) 569-4460, primusline.com

Primus Line is the manufacturer of the Primus Line system, an innovative relining solution for the trenchless rehabilitation of pressure pipes for different applications such as water, gas and oil.

The system consists of a flexible, aramid-reinforced liner and specially developed end fittings. Clients benefit from long insertion lengths of up to 2,500 meters in one single step and the product’s ability to traverse bends of up to 45 degrees.

Primus Line is not bonded to the host pipe and is self-supporting. An annulus remains between Primus Line and the host pipe.

Reline America

(888) 998-0808, relineamerica.com

Reline America manufactures Alphaliner, a complete system that’s custom-built to fit

the infrastructure protection and rehabilitation needs, and enhance the efficiency, of municipalities, DOTs, railways, airports and other industries.

This seamless, ultraviolet-light-cured, glass-reinforced (UV GRP) liner is available in diameters ranging from 6 to 72 inches (15.24 cm to 182.88 cm) and lengths of more than 1,200 feet (366 meters), and can accommodate a variety of pipe shapes, ranging from circular, ovoid and arch, to rectangular and special cross-sections.

We also customize our equipment to make installation a totally user-friendly process – with risk-management and profitability top-of-mind.

SAERTEX multicom

(704) 584-4059, saertex-multicom.com

SAERTEX multiCom offers an innovative solution for rehabilitation of potable water mains. With an application range of 8- to 48-inch diameter and pressure ratings of close to 600 psi in its smaller-diameter range, SAERTEX-LINER H2O provides for one of the strongest and most robust solutions in the CIPP market.

Cured with the latest UV technology under constant monitoring, and certified and approved by NSF61, SAERTEX-LINER H2O is engineered for strength, durability and longevity.

Vortex Companies

(855) 949-3441, vortexcompanies.com

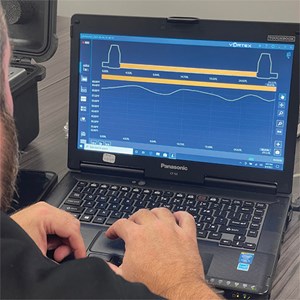

It’s crucial for installers to verify the quality of a CIPP liner’s cure to ensure performance. The Vortex Companies’ VeriCure CIPP Curing Monitoring System addresses this critical need to confirm a complete, consistent cure to prevent CIPP failure.

As the only continuous CIPP monitoring system, VeriCure eliminates guesswork and produces a validation report to verify the liner is installed to spec, ensuring it will perform as designed.

VeriCure monitors the liner’s temperature profile through the full length of the line utilizing optical fiber cable, significantly reducing the risk of lifts, delamination and over-tensioning to ensure a quality cure, every time. •

Comments