November 2020 Vol. 75 No. 11

New Products

TD Williamson

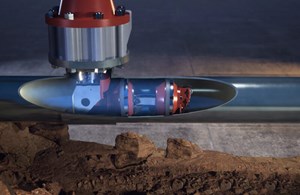

Global pipeline solutions provider T.D. Williamson (TDW) introduced two isolation innovations for the gas distribution market.

ProStopp DS offers the first, low-pressure, double block-and-bleed isolation technology via two plugging heads with a bleed port in-between them. This allows product to bleed through the housing, so there is less hardware on the line.

Designed from schedule 10-60 pipe and rated to 285 pounds per square inch (19 bar), ProStopp DS is currently available for 6-inch to 12-inch pressurized carbon steel pipelines, and is compatible with TDW valves and fittings.

Its isolation technology features a hydraulically activated, energized seal that conforms flawlessly to multiple internal pipe diameters. The variable design increases the likelihood of first-time sealing success and eliminates leaks, even in tough crevices and weld seams.

“Because the energized seal accommodates multiple inner diameters, it takes the guesswork out of tool configuration, while drastically reducing inventory needs,” said Ryan Ragsdale, HT & P senior product manager.

“The built-in chip sweep helps ensure a leak-proof seal, while also reducing operation requirements,” he added. “And because the tool is ground-operated, the technician makes fewer trips up and down the ladder, completing jobs faster and with less risk.”

POLYSTOPP Quick Connect allows operators to isolate a polyethylene line twice as fast as other methods, while preventing the damage associated with squeezing.

According to Ragsdale, POLYSTOPP takes less than 10 minutes to tap and isolate a pipeline. Installing the tapping, plugging and completion machines onto the valve takes about 20 seconds each, and removal is just as fast.

Comments