August 2020 Vol. 75 No. 8

Currently at CUIRE

Use of Spray Applied Pipe Linings as Structural Renewal for Gravity Stormwater Conveyance Conduits

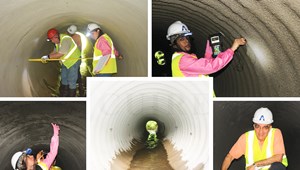

Since December 2017, a group of researchers from CUIRE at the University of Texas at Arlington has been developing design methodologies for structural applications of spray applied pipe linings (SAPLs) in the renewal of culverts and drainage structures. The project includes several partner companies – Structurepoint Inc., LEO Consulting and Rehabilitation Resource Solutions – and is funded through the National Cooperative Highway Research Program (NCHRP).

Introduction

The key issue in current design guidelines is whether the existing pipe is structurally sound enough to continue to carry the earth, and live and hydrostatic loads imposed on it. It is well-known that existing flexible pipes gain structural strength through the soil-structural interaction, thus making them a composite system.

There are many documented instances of existing corrugated metal pipes, with significant invert loss, that continue to hold their shape, due to the load carrying capacity of the surrounding soil. If the existing pipe is structurally sound enough to continue to maintain shape and carry the earth and live loads imposed on it, then several internal lining techniques might be applicable. These include sliplining (SL), cured-in-place pipe (CIPP), spray-applied pipe lining (SAPL), and close-fit pipe (CFP).

It is important to note that any lining technique used must be preceded by restoration of the surrounding soil integrity. Voids in the embedment or invert must be filled completely to restore the strength provided by the soil. The thickness and strength of the internal liner, in this case, is required to be sufficient enough to resist only the hydrostatic loads imposed by the groundwater table.

Although these methods are designed to increase the structural load carrying capacity of the existing pipe, they do resist continued structural deterioration and maintain the soil-structure interaction composite system. The linings are required to resist the live loads and dead loads. However, the dead loads are calculated in a manner similar to what is required in a steel tunnel liner plate structure, according to AASHTO LRFD Bridge Design Specifications, Section 12.13. Consequently, the above linings are designed as semi-structural renewal methods.

If a pipe is deteriorated to the point that it cannot continue to carry the earth loads and live loads imposed on it, it will lose its shape and collapse. This may be catastrophic, or may occur over an extended time, depending on the rate of surrounding backfill loss. Renewal methods applied at this stage are designed to serve as standalone structures.

Methods such as sliplining, cured-in-place pipe, panel lining or close-fit pipe might be appropriate, but the wall thickness of the new pipe will be thicker than in the previously described case. As a result, the installer must assure that the surrounding soil strength is restored; otherwise, subsidence of the soil may occur after the renewal method is completed.

The existing pipe must maintain hydraulic capacity, further limiting renewal at this stage, due to the reduced cross-sectional area. If hydraulic capacity cannot be assured, the new pipe can, under certain conditions, be replaced via in-line replacement techniques, such as pipe bursting or hand tunneling. Another renewal method is “invert concrete field paving” for corroded corrugated metal pipes.

If none of the trenchless renewal methods can be employed (because of factors such as shape, soil voids and localized collapse, alignments, size, joint settlements, hydraulic capacity problems), the pipe might have to be replaced using a parallel line installed by the trenchless construction methods. In some cases, multiple trenchless renewal methods, or even a combination of open-cut and trenchless methods, might be considered. The latter approach would apply when the surface disruption associated with conventional open-cut technique could be tolerated.

Project details

To reduce emergency projects and impacts to the travelling public, departments of transportation (DOTs) can use spray-applied pipe linings (SAPLs) to renew deteriorated gravity stormwater conveyance conduits and culverts, provided they are discovered prior to loss of soil-structure interaction. To implement this new technology, the American Association of State Highway Transportation Officials’ National Transportation Product Evaluation Program developed a Technical Committee for SAPLs.

The SAPL Committee consists of DOTs, manufactures of resin-based material, and manufactures of cementitious based materials. An early request from the DOT members was to ensure that the spray-applied lining functioned as a structural liner. However, it was quickly realized that no standardized structural design methodology existed for this technology. Manufacturers utilize different design methodologies, with some using CIPP ASTM F1216 methodology and others using various classical analytical structural design equations developed for other purposes. A gap in knowledge was identified and preliminary discussions for research among the SAPL Committee members took place.

The research needs statement was posted through Ohio DOT’s Research Program, and the National Cooperative Highway Research Program and CUIRE were selected. The funding commitment was achieved by Del., Fla., Minn., N.C., N.Y., Ohio and Penn. DOTs, and led by Ohio DOT. Other DOTs are encouraged to join, to expand the research to their states’ particular needs.

Objectives and methodology

The primary objective of this three-year research is to develop design equations for structural renewal of gravity stormwater conveyance culverts using SAPLs for both cementitious and resin-based materials, and for circular pipe and pipe arch shapes with spans larger than 36 inches. Design equations developed with this project will use loading, as detailed in AASHTO’s Load and Resistance Factor Design Bridge Design Specifications, and will be applicable for round and arch shapes.

All parameters of the host culvert that may impact the design thickness, such as vertical or horizontal deflections, unsymmetrical racking, section loss, cracks, material geometry (corrugations), or protrusions such as bolts and flanges, will be considered. Additionally, practical limitations on the use of these design equations will be included.

The methodology for this research includes:

Structural Design Methodology for Spray Applied Pipe Liners in Gravity Storm Water Conveyance Conduits

- Survey of US DOT’s and Canadian Agencies

- Literature Search/Participation Material Vendors

- Evaluation of Additional Reinforcement

- Evaluation of Benefits for Filling Corrugations

- Review the Cured in Place (CIPP) Design Equations

- Field Data Collection at Participating State DOTs

- Construction and Environmental Cost Analysis

- Soil Box Testing

- Finite Element Modeling

- Develop Structural Design Equations

- Develop Performance Construction Specifications

- Develop a Recommended Structural Design Equations

- Draft Final Report and Fact sheet

- Final Report and Presentation

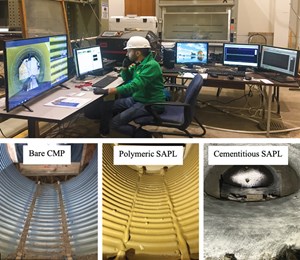

Update on Soil Box Testing Results

As a main part of this study, 15 pipe samples in five separate sets were tested with and without SAPL in the soil box located at CUIRE’s facility at the University of Texas at Arlington. The soil box has dimensions of 25 by 12 by 10 feet, equipped with a 330 Kips actuator installed on a reaction steel frame. The SAPL-lined samples over invert-cut circular and arch shape CMPs with 0.25-, 0.5- and 1-inch polymeric, as well as 1, 2, and 3 inches of cementitious material, were tested and compared with bare invert-cut samples.

The overall results showed that application of polymeric and cementitious SAPLs increased the ultimate loading capacity of the invert deteriorated circular and arch CMP culverts approximately from 80 percent to 140 percent.

Performance Specifications

- Reference Standards

- Submittals

- Inspection Records

- Vendor Qualifications

- Delivery, Storage and Handling

- Warranty

- Design Objectives

- Materials

- Cleaning, Inspection and Preparation

- Installation – Filling Corrugations

- Quality Requirements – Required Testing

- Acceptance Criteria

Comments