October 2015 Vol. 70 No. 10

Features

Summary, Application Of Regulations For Pipe Bursting Asbestos Cement Pipe

by Edward Alan Ambler, P.E., LEED AP

Editor’s Note: This is the second installment of a two-part series regarding the rehabilitation of asbestos cement pipe.

Part one was published in the September issue of Underground Construction.

The city of Casselberry is a medium, size town in suburban Orlando that is considered to be 95 percent developed. Much of the city has been developed for many decades with a significant amount of the development occurring between 1950 and 1980. This time frame occurs with the increased popularity of installing asbestos cement (AC) pipe within the United States.

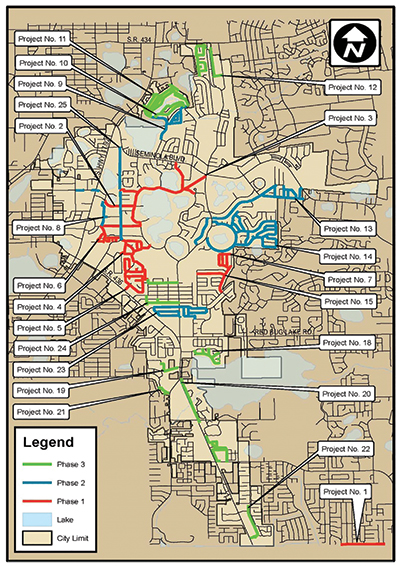

There are widely varying estimates as to the amount of AC pipe installed within the United States and Canada but some estimates conclude there could be as much as 630,000 miles installed (Von Aspern, 2009). Prior to 2009, the city was appropriating $300,000 per year to replace existing potable water mains throughout the city, which replaced approximately one mile per year. The city owns and maintains 215 miles of potable water main in its distribution network including 95 miles of AC pipe. The assumed 50-year service life of the existing asbestos cement pipe was almost over and the current replacement schedule was not sustainable, requiring 215 years to replace the entire distribution network (Ambler, et. Al 2014). Luckily, the city of Casselberry received a substantial grant from the Florida Department of Environmental Protection through the American Recovery and Reinvestment Act to embark on a project focused on rehabilitation of 35 miles of asbestos cement pipe. This allowed Casselberry to make dramatic headway into positive rehabilitation of the city’s buried pipeline infrastructure.

There are widely varying estimates as to the amount of AC pipe installed within the United States and Canada but some estimates conclude there could be as much as 630,000 miles installed (Von Aspern, 2009). Prior to 2009, the city was appropriating $300,000 per year to replace existing potable water mains throughout the city, which replaced approximately one mile per year. The city owns and maintains 215 miles of potable water main in its distribution network including 95 miles of AC pipe. The assumed 50-year service life of the existing asbestos cement pipe was almost over and the current replacement schedule was not sustainable, requiring 215 years to replace the entire distribution network (Ambler, et. Al 2014). Luckily, the city of Casselberry received a substantial grant from the Florida Department of Environmental Protection through the American Recovery and Reinvestment Act to embark on a project focused on rehabilitation of 35 miles of asbestos cement pipe. This allowed Casselberry to make dramatic headway into positive rehabilitation of the city’s buried pipeline infrastructure.

In continuation of Part 1 of this series, rehabilitation of the existing AC pipe is governed under the National Emissions Standards for Hazardous Air Pollutant (NESHAP), a sub section of the Clean Air Act. Congress established much of the basic structure of the Clean Air Act in 1970 and made major revisions in 1977 and 1990. The Environmental Protection Agency is responsible for implementation of the regulations established in the Clean Air Act (http://www.epa.gov). Modifications to the Clean Air Act require Congress to approve any changes. NESHAP governs rehabilitation of existing AC pipe line by establishing limits on the release of asbestos fibers during handling of the existing AC pipe line.

NESHAP provides for the distinction of asbestos-containing material, (ACM). Friable, or Regulated ACM (RACM) is defined as any material containing more than 1 percent asbestos that, when dry, can be crumbled, pulverized or reduced to powder by hand pressure. Non-friable ACM is any material containing more than 1 percent asbestos that, when dry, cannot be crumbled, pulverized or reduced to powder by hand pressure.

Two categories

Two categories

EPA defines two categories of non-friable ACM, Category I and Category II non-friable ACM. Category I non-friable ACM is any asbestos-containing packing, gasket, resilient floor covering or asphalt roofing product which contains more than 1 percent asbestos. Category II non-friable ACM is any material, excluding Category I non-friable ACM, containing more than 1 percent asbestos that, when dry, cannot be crumbled, pulverized, or reduced to powder by hand pressure (Sec. 61.141) (Ambler et al., 2012). This essentially means asbestos products that can be crumbled by hand pressure to release asbestos fibers are considered to be hazardous. I have not been able to crumble an AC pipe fragment by hand and I have actually tried.

NESHAP provides exemptions from its regulations based on the quantity of ACM. For AC pipe, the quantity threshold is 260 lineal feet regardless of diameter, in one calendar year. Other exemptions from NESHAP or clarifications of its requirements for AC pipe have been provided by interpretive letters in response to questions posed to EPA (EPA, 1990). These clarifications state that any AC pipe is exempt from NESHAP if it is removed intact and disposed in a waste disposal site, capped and abandoned in place or grout-filled and abandoned. If the existing

AC pipeline undergoes pipe bursting, it becomes subject to NESHAP provisions (Ambler et al., 2012). The Water Research Foundation data collected on the city of Casselberry AC pipe bursting project as summarized in WRF Report #4465 has been the most data collected on an AC pipe bursting to date (Matthews, et. al, 2015). Since no significant studies had been performed on remaining AC pipe fragments after pipe bursting when EPA offered its clarification in the 1990s, it may be timely to pursue further clarification from EPA in combination with the new data presented by the Water Research Foundation.

EPA has mainly left enforcement and interpretation of NESHAP’s applicability to AC pipe bursting up to the state regulatory agencies. A survey of 50 state asbestos regulatory agencies conducted by Battelle found that the majority of states adhere to NESHAP regulations and conclude that any process that makes asbestos fibers friable would be regulated and requires either licensed contractors or should not be attempted at all. According to WRF data, most utilities preferred to abandon AC pipe in-place when possible, or replace it by excavating. Although other methods of AC pipe renewal exist, such as CIPP, SIPP, pipe reaming and pipe bursting, utilities were hesitant to employ them based on their understanding and interpretation of NESHAP and state regulations (Matthews, et. al, 2015).

Many engineers, contractors and utility providers strongly disagree that pipe bursting AC pipe coverts the previously non-RACM AC pipe into friable RACM, including the author of this article. The extensive sampling described in WRF Project #4465 clearly indicates that pipe bursting does not release asbestos fibers into the air creating a hazardous environment for pipe rehabilitation workers, residents and others within the working area (Matthews, et. al, 2015). A working procedure has been developed in Florida that regulators and industry members are utilizing. Many other utilities such as Miami-Dade Water and Sewer Department, Cooper City FL, and Port St. Lucie, FL, have started

using this procedure.

Concerns

As NESHAP has been written, the area directly on top of AC pipelines that have been pipe burst and remain in place are considered to be in-active hazardous waste sites. These sites are required to be memorialized by recording the locations as an in-active hazardous waste site on the property deed for the property. However, public right-of-ways do not maintain a property deed for this process to be implicitly met. This conflict brought industry and Casselberry project leaders to Washington D.C. to meet with top EPA staff to discuss pipe bursting and the applicability of NESHAP to pipe burst AC pipe in 2010. EPA officials embraced the environmental, social and economic benefits of pipe bursting AC pipe and understood the risks of asbestos exposure due to pipe bursting AC pipe would be mitigated over traditional pipe removal methods. While pipe bursting was met with a positive response, modification of the existing NESHAP regulations would require an Act of Congress to complete. EPA officials recommended industry representatives present the EPA Administrator with an “Administrator Approved Alternate” process that can cover AC pipe bursting (Ambler et al., 2012).

Some regulators, utility providers and engineers still have concerns that the remaining pipe fragments will be excavated and expose others to the risk of asbestos inhalation. Potential future excavation of the fragments of AC pipe will be limited to utility crossings, unintended resident excavation but primarily, future rehabilitation of the new HDPE pipeline. Subsequently, the remaining fragments of

AC pipe would closely surround the new HDPE pipeline and excavators would stop digging once the HDPE pipe was discovered (Ambler, et. al, 2014).

If another utility company or underground excavator were required to perform excavation in the vicinity of the remaining AC pipe fragments, they would likely only be doing so where the proposed utility crosses the remaining AC pipe fragments, not paralleling the remaining AC pipe fragments. Typically, any third party excavation along the existing pipe and AC pipe fragments would be less than the 260 linear feet exemption previously established in NESHAP (Ambler, et. al, 2014).

During construction of the Casselberry project, the project team encountered significant

opposition to the concept of pipe bursting AC pipe. A right-of-way agent that controlled the construction activities within a neighboring agencies’ right-of-way expressed concern that residents would “crush up the remaining AC pipe fragments and sniff it.” It is highly unlikely that residents would perform such an activity. However, this statement highlights some of the unfortunate misconceptions of the AC pipe bursting activities. AC pipelines generally maintain a depth of two feet or greater. If a property owner were to excavate to plant a new tree, they typically would not excavate greater than the two feet depth of cover. The linear footage of remaining AC pipe fragments exposed would still fall under the 260 linear feet category that can be removed as regular construction debris (Ambler, et. al, 2014).

Future handling

Utility owners performing AC pipe bursting projects must acknowledge the future handling requirements for the AC pipe fragments remaining in the ground. Emergency repair procedures performed on newer HDPE pipe will typically disturb less than 260 linear feet of the remaining AC pipe fragments and the risk is clearly mitigated. If the utility owner chooses to replace the remaining production pipe in its entirety, they will have to acknowledge appropriate handling of the remaining AC pipe fragments. Subsequently, significant release of asbestos fibers from the remaining AC pipe fragments could only occur through excavation and crushing of the remaining pipe fragments, which is not likely. Once the pipe burst AC pipe fragments remain in place surrounding the replacement pipe, the risk of exposing people to asbestos fibers has been mitigated (Ambler, et. al, 2014). AC pipe bursting should be recognized as the preferential method of replacing existing AC pipelines since the majority of the force executed on the existing pipeline occurs underground and the existing pipeline stays there.

This two part series on asbestos cement pipeline rehabilitation attempted to clarify aspects surrounding AC pipe, including characteristics of AC pipe, potential installation dates, estimates as to the quantities of AC pipe installed in the US, available options for rehabilitation of the AC pipeline, data collection efforts covering management and rehabilitation of AC pipelines, regulations governing working with AC pipelines and potential risk to workers and the general public when performing rehabilitation options or leaving the AC pipe fragments in place. Hopefully, this extensive information will allow utility owners to fully understand the implications of positive rehabilitation of AC pipelines. The city of Casselberry has successfully performed AC pipe bursting to rehabilitate 35 miles of AC pipe while meeting all existing regulations and minimizing risk to its workers and the general public. The city has elected to move forward to progressive utility distribution system rehabilitation while leaving the fragments of AC pipe behind.

ABOUT THE AUTHOR: Alan Ambler, P.E., LEED AP, is the Water Resources Manager for the city of Casselberry, FL. Ambler has 15 years of diversified experience in utility management and design, roadway and drainage design, utility coordination and construction management. His career efforts have brought him from Dubai to Alaska to manage infrastructure development for large scale developments such as Dubai Maritime City and the World Islands in Dubai to the city of Ketchikan’s onsite construction inspection representative for two $30 million+ cruise ship berth projects in Alaska. Ambler now manages the utility department consisting of 39 employees for the city of Casselberry, including day to day operations and planning, design and execution of the $6 million per year capital improvement plan.

Cited Research:

Matthews, John C. and Ryan Stowe and Jason Lueke. Water Research Foundation. Water Environment Research Foundation. US EPA. 2015.

Von Aspern, Kent. “End of the Line.” Public Works Magazine. March 2009.

Ambler, Edward Alan, John Matthews, William Thomas. “Casselberry Asbestos Cement Pipe Bursting Project: Moving Forward by Leaving it Behind.” North American Society for Trenchless Technology. April 2014.

Ambler, Edward Alan, William Thomas. “Applicability of NESHAP to Rehabilitating Asbestos-Cement Pipelines.” North American Society for Trenchless Technology. April 2012.

American Water Works Association. “Work Practices for Asbestos Cement Pipe.”

Comments