October 2015 Vol. 70 No. 10

Features

Reversing the Cause of Infiltration & Restoring Collection Systems

The single biggest sewer challenge facing engineers and municipalities is inflow and infiltration (I&I). I&I is destroying our underground infrastructure and shortening the critical life-span of our existing sewer collection systems. If this problem is not resolved, structural rehabilitation becomes more costly and complete restoration becomes mandatory. Underground systems may be out of sight, but should never be out of mind.

The single biggest sewer challenge facing engineers and municipalities is inflow and infiltration (I&I). I&I is destroying our underground infrastructure and shortening the critical life-span of our existing sewer collection systems. If this problem is not resolved, structural rehabilitation becomes more costly and complete restoration becomes mandatory. Underground systems may be out of sight, but should never be out of mind.

I&I causes surcharging which results in exfiltration as well as infiltration. This vicious cycle allows soil fines and debris to enter our collection systems through joints and cracks – creating voids outside the pipes – leading to unstable sewer trenches and creating the potential for sinkholes. Further, infiltration reduces total system capacity, causes burdens to pump operations, and generates 50% excess flow to our treatment facilities, costing the rate-payer unnecessarily.

In order to reduce infiltration, engineers and municipalities must first assess the condition of mainline pipes, laterals, lateral connections and manholes to determine whether restoration requires structural or non-structural repair for each component. There are many structural rehabilitation options, but there is only one non-structural, no-dig technology specifically engineered to stop infiltration—systematically Test, Seal and Validate with injection grout.

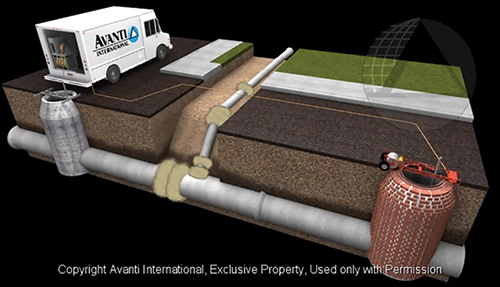

In non-man entry structures – like mainlines – acrylic grout is injected through joints, cracks and defects into the surrounding soil via remote packer. With visual confirmation from a CCTV camera, the packer is centered over the pipe joint, bladders are inflated on either side of the joint, and air pressure tested. If the joint does not leak air, it will not leak water. With no injection necessary, the packer and camera advance to the next joint and repeats the air test process. If the joint fails an air test, an acrylic grout is injected through the defect and into the soil. With a controlled set-time, the two-part acrylic liquid turns into a gel, and then cures to form a solid matrix with the soil creating an impermeable, positive seal around the joint and substrate material. The joint is then air tested again to validate a successful seal and the packer advances to the next joint. Remote packers are available in a variety of sizes and can accommodate pipes as small as 4 inches for laterals and as large as 144 inches for combined mainline sewers.

The remote packer process is similar for sealing laterals and lateral connections. Once the packer is positioned correctly under the lateral connection using CCTV camera, the bladders inflate and a rubber sleeve expands up the pipe. Once fully expanded, an air test is performed and acrylic grout is injected under pressure and forced outside the pipe through the defects. The most common specification is to test and seal the first six feet of the lateral, but with a 38 foot sock, an effective sealing distance up to 30 feet reaches to the right of way (ROW) or private property line.

While CIPP Liners are designed and constructed to enhance the structural integrity of the host pipe, they will not eliminate the problem of infiltration. Tests have shown that infiltration from joints and cracks eventually re-enters the system at lateral cut-outs, connections to manholes, and/or defects in the liner. Complementary to one another, the combination of injection grouting to stop infiltration followed by CIPP Lining for structural defects provides the best long-term performance for rehabilitated sewer systems.

Injection grout is the only proven solution specifically engineered to stop infiltration at all four-points of entry: Mainlines, Manholes, Laterals, and Lateral Connections. It is the low-cost/high-reward, answer for structurally sound systems, and the ideal complement to CIPP Lining for total system sealing.

Grout First has become the new battle cry in municipalities like Naperville in Illinois, Sullivan’s Island in South Carolina and Miami-Dade in Florida. Communities large and small have cost-effectively reversed the cause of infiltration and restored the collection system by stopping leaks, stabilizing surrounding soils, and controlling unwelcome groundwater with the use of injection grout.

For more information on solving your infiltration problem, call 800.877.2570 or visit www.AvantiGrout.com for animations, videos, technical data sheets, and documented successes.

The Capabilities Guide is a yearly feature in Underground Construction’s October issue. It is a special advertising section in which advertisers are given free matching space to highlight their company, services and products.

Comments