November 2022 Vol. 77 No. 11

New Products

New Products

Innovative, Stringer Bead Brush Sets Standard in Welding, Pipeline, Metal Fabrication

Once again bringing industry-leading innovation to the pipeline, welding and metal fabricating markets, Osborn introduced a new double-stringer bead brush that offers twice the life and aggression of its already proven and industry-leading TufBrush stringer bead brush.

The Honey Badger Double Stringer Bead Brush establishes a new standard in welding, as there are currently no other brushes on the market that can achieve what it can. Built with two sets of wire knots on a unique face plate and nut, the brush can hit both sides of the root, or hot pass, while cleaning out any slag or debris of a weld.

For 135 years, Osborn has been dedicated to offering the best solutions for mechanical treatment challenges, relying on customer input, and collaborating with those customers to improve the quality of its products.

Consistent with that tradition, welders and similar professionals are participating in a testing period. Results will enable the company to further improve the final product.

“The Honey Badger Double Stringer Bead Brush already promises to offer a longer lifespan, a faster cut, less operator fatigue and less effort, so we’re excited to see the impact it has on our industry,” said Brian Keiser, Osborn’s vice president of operations.

The Honey Badger Double Stringer Bead Brush can currently be pre-ordered and will be available to purchase in 2023. Right now, the product is patent pending.

Osborn is the world’s leading supplier of surface treatment solutions and high-quality finishing tools for industrial and commercial applications within material finishing, deburring, cleaning, honing and surface polishing segments. Founded in 1887, the company now includes operations in 13 countries and serves customers in more than 100 countries. UC

FOR MORE INFORMATION

Osborn (U.S.), (800) 537-8449, osborn.com

Ditch Witch Delivers Powerful Plowing in a Reimagined Package

Contractors can get a new spin on a reliable classic with the

PT37 ride-on plow/trencher from Ditch Witch. It brings next-generation durability and usability to a proven model, preferred for fiber installation, while retaining the simple, mechanical design preferred by many contractors.

The new machine is a dedicated plow with an optional trencher, reel-carrier and hydra-bore configuration to meet a wide range of job-site needs. An adjustable side-facing seat allows the operator to see all four tires and the plow box while operating.

Designed for ease of use and storage, PT37 features a compact footprint, able to scale down to just 36 inches wide, so users can enter standard gates and access tight workspaces. Its tires provide cost savings compared to a tracked version and minimizes the impact on yards. An optional dual-wheel configuration provides added traction and stability. A foldable ROPS design allows users to keep the PT37 on a trailer for easy parking and storage in garages.

Further improving its functionality, PT37 is largely mechanical and features a simplified control display. It also requires less maintenance due to its simplified exhaust cleaning and fewer grease points.

A Yanmar diesel engine provides gross 36.8 horsepower (27.5 kW) at 3,000 RPM to deliver constant performance while plowing, trenching or boring. An optimized plow design provides down pressure to maintain consistent plowing up to 24 inches deep in a variety of conditions. UC

FOR MORE INFORMATION

Ditch Witch, (800) 654-6481, ditchwitch.com

John Deere Continues Performance Tiering Rollout with Large Wheel Loader Line

John Deere launched its line-up of large wheel loaders as part of its Performance Tiering Strategy. Now available in the U.S. and Canada, the 744, 824, 844 and 904 P-tier wheel loaders offer advanced productivity features, increased job-site reliability, optimal operator comfort, and enhanced serviceability to help improve machine uptime.

Included in the base models of all P-tier wheel loaders are a variety of features aimed at increasing performance on the job. High-capacity, heavy-duty axles with standard axle cooling filtration deliver durability in difficult conditions compared to previous models.

With advantages, such as fuel-efficient engines, operators of the P-tier machines can do more while burning less fuel. The electrohydraulic (EH) controls with multifunction programmable buttons offer the highest level of operator comfort, while the material-handling buckets with integrated spill guards and curved side cutters make for easier and more intuitive operation.

Combining the productivity-increasing features with a redesigned cab and controls, the 744 P-tier, 824 P-tier, and 844 P-tier Loaders provide the muscle needed for operators to work comfortably and efficiently. The redesigned cab gives more space, storage, and enhanced visibility, as well as adjustable heated and ventilated seats and an upgraded HVAC system.

All P-tier Wheel Loader models also include technology options such as Advanced Vision System and Advanced Obstacle Detection System for improved visibility and increased situational awareness. New, higher resolution digital cameras, dedicated display, and escalating audible alerts inform operators when obstacles are in the path of their machine. This feature also overlays a projected vehicle reversible path within the same dedicated monitor, enhancing the operator’s experience and control.

FOR MORE INFORMATION

John Deere, (844) 809-1508, johndeere.com

Yanmar

Yanmar Compact Equipment offers the ViO80-1A and SV100-2A, the largest models in its mini excavator line. The machines provide the performance, efficiency, technology and reliability needed for tough jobs, allowing for maximum productivity in construction, landscaping and utility applications.

With zero tail-swing, the signature feature pioneered by Yanmar, the ViO80 excavator can rotate next to a structure with far less risk of hitting it. The larger SV100’s ultra-tight tail swing has just 6.7 inches of overhang.

These mini excavators offer exceptional performance for their size classes. The 8-ton-class ViO80 weighs 18,136 pounds with 56.9 horsepower and a maximum digging depth of 15 feet 4 inches. The 10-ton class SV100 has a 21,550-pound operating weight, 72 horsepower and a maximum digging depth of 15 feet 9 inches.

The ViO80 and SV100 offer several standard features that promote operator comfort and easy operation: ECO Mode, Auto-Decel Mode and auto shift 2-speed travel. As an added convenience, Yanmar’s hydraulic quick coupler, also standard, allows fast and easy changing of attachments.

Both machines have spacious cabs designed to provide maximum elbow and leg room. The mini excavators feature standard heating and air conditioning systems and sturdy, sound-blocking, anti-vibration construction for a smooth, quiet ride and comfortable operator experience year-round.

Offering even more application versatility, SV100 includes a lever-controlled backfill blade, along with an LCD monitor displaying key operating information and maintenance interval notifications.

The mini excavators are powered by a fuel-efficient Yanmar Tier 4 Final engine, with legendary Yanmar reliability and performance, and have a standard second PTO with flow control for maximum utility.

Vivex/MetroTech

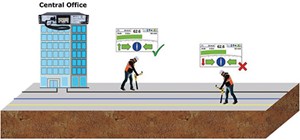

Fiber optic cables are a critical part of modern life carrying vast amounts of data to businesses, individual internet users, schools and emergency services. Marking the position of cables reduces the danger of third-party damage.

The FLS-2 is a high-performance, long-distance fiber-optic cable locating and monitoring transmitter. It can be used for long-haul fiber lines and metropolitan loop networks, as a central office or rack-mounted regen system. All features of this 50-watt transmitter can be accessed remotely or locally with the hand-held touch screen.

The system consists of the FLS-2 Rack Mounter Transmitter, with switching relays, and hand-held Receivers (locators), which pick up the signal. It works on the concept of positioning a permanently installed transmitter, at a suitable regen station, and switched remotely by its telephone interface over the internet, or fixed telemetry control.

When instructed, FLS-2 lifts any local grounding and inputs a low-frequency current, typically 512Hz, into the sheath of the cable. This signal current travels along the cable and can be accurately located above ground using a suitable electromagnetic detector. When the signal is not required, the FLS-2 transmitter automatically switches the cable sheath back to the station ground, minimizing danger from induced currents etc.

Since FLS-2 can transmit locate signals over many miles of cable, installing them at strategic locations throughout the network ensures good locate coverage.

Traditionally, a portable transmitter is used to apply a signal to the cable. This requires identifying an access point close to the area that must be located – usually via a maintenance hole and a signal clamp to induce a signal at that point.

Caterpillar

cat.com

Building on the success of its M-Series compact wheel loaders, Next Generation CAT 906, 907 and 908 wheel loaders boast improved operator experience, upgraded drive and powertrain, and overhauled hydraulics and structures, making them an optimal fit for many applications.

A re-engineered operator’s station leverages exclusive CAT technologies and provides larger wheel loader model comfort on a smaller platform.

The new sealed and pressurized cab improves the operator experience, while keeping previous design functional aspects like raised floor pedals and two doors to make cab cleaning easier. Optimum visibility is achieved with larger standard side mirrors, optional parabolic lens electric and heated mirrors, and front and rear camera options.

Seat-mounted controls improve operating ergonomics of the new loaders. A multifunction joystick also elevates safety, by controlling travel direction and speed, proportional auxiliary flow, differential lock, and constant hydraulic flow.

A first for this class size, new in-cab-programmable kickouts, with high-definition rotary sensors mounted to the loader arms, better protect operators from unwanted shock and vibration – and save up to 20 percent of bucket cutting edge life.

The heart of the new cab design is the Next Generation control monitor, which offers a range of real-time machine operating information. It allows the operator to configure hydrostatic transmission response, auto engine idle shutdown and a utility powertrain mode that provides operators with a more intuitive means of controlling ground and engine speed – ideal when working with hydromechanical attachments.

Upgraded drive and powertrain deliver faster roading speeds and drive train performance. The new Cat C2.8 engine delivers the same 74-horsepower (55.7-kW) gross power as the previous engine, with 13-percent more torque. It meets EU Stage V and U.S. EPA Tier 4 Final emission standards, and alternative emissions packages are available.

The shift-on-the-go transmission offers increased roading speeds of 25 miles per hour (40 km/h), and larger fuel tank capacities – 30 percent for the 906 and 12 percent for 907 and 908 – deliver extended work cycles.

Comments